Introduction to Welding Gas Flow Meter

A welding gas flow meter is an essential tool for any welding professional or workshop, designed to control and measure the gas used during the welding process. This device ensures the precise flow of shielding gases such as argon, carbon dioxide, and helium, which are crucial for achieving optimal weld quality. By accurately regulating gas flow, these meters not only enhance welding performance but also contribute to cost efficiency by minimizing gas wastage.

Types of Welding Gas Flow Meters

There are various types of welding gas flow meters available, each tailored to specific applications and user needs. Understanding these types can help you select the best option for your welding projects. Here are some common types:

- Mechanical Flow Meters: These utilize a rotating mechanism to measure gas flow and provide a visual reading. They are often cost-effective and easy to use.

- Digital Flow Meters: Equipped with electronic sensors, these offer precise readings and often come with advanced features like flow alarms and data logging.

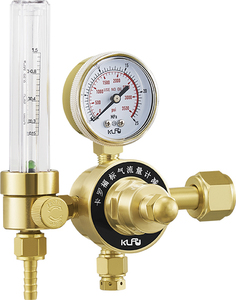

- Variable Area Flow Meters: Also known as rotameters, these meters utilize a float that rises and falls within a tapered tube, allowing for a simple visual indication of flow rate.

- Mass Flow Meters: These measure the mass of the gas flowing rather than its volumetric flow, providing unmatched accuracy and reliability, especially for more sophisticated welding operations.

Applications of Welding Gas Flow Meter

The applications of welding gas flow meters are vast and integral to various industries. The right meter can make a significant difference in the efficiency and quality of welding projects. Here are common applications:

- Metallurgy: Ensures uninterrupted flow of protective gases in processes like TIG and MIG welding.

- Automotive Repair: Used in body shops to provide the necessary gas flow for quality repairs.

- Manufacturing: Critical for large-scale production where consistent welding quality is paramount.

- Fabrication: Essential in metal fabrication shops where accuracy in gas flow translates to precision in workmanship.

Advantages of Using a Welding Gas Flow Meter

Incorporating a welding gas flow meter into your welding arsenal provides significant advantages that ultimately enhance both the efficiency of the process and the quality of the final welds. Here are the key benefits:

- Improved Weld Quality: Precise control of gas flow ensures the right shielding environment, which is critical for clean and strong welds.

- Cost Efficiency: Minimizes gas wastage, leading to reduced overhead costs and improved budget management.

- User-Friendly: Many models come with easy-to-read displays and straightforward controls, making them accessible for both novice and experienced welders.

- Durability: Built to withstand harsh workshop environments, most welding gas flow meters are made from robust materials ensuring long-lasting performance.

Conclusion

In summary, a welding gas flow meter is not just an accessory but a vital component for achieving excellence in welding operations. With various types tailored for different applications and numerous advantages like improved weld quality and cost savings, investing in a quality welding gas flow meter can significantly elevate your welding projects to new heights of proficiency and success.