Popular in your industry

Top categories

About tube bead roller

Understanding Tube Bead Rollers

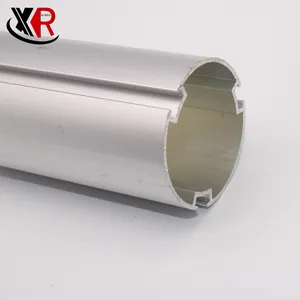

Tube bead rollers are specialized tools used in the manipulation and shaping of tubes and pipes. These devices play a crucial role in various industries, allowing for the creation of consistent, precise beads on metal tubing. The bead roller's primary function is to add rigidity to the metal tubes, enhancing their durability and structural integrity. This process is essential in applications where tubes must withstand pressure or maintain a specific form.

Types and Materials

The market offers a diverse range of tube bead rollers, each designed to cater to different materials and sizes of tubing. Common materials used in the construction of these rollers include steel, carbon steel, and stainless steel. These materials are chosen for their strength and resistance to wear, ensuring the longevity of the tool. Users can select from various models, which may differ in terms of the diameter they can handle, the thickness of the metal they can work with, and their operational methods, whether manual or powered.

Applications and Features

Tube bead rollers find their applications in numerous fields, from automotive exhaust systems to HVAC installations. The versatility of these tools is reflected in their adjustable features, such as the ability to change roller dies to fit different tube sizes and profiles. Advanced models may offer features like variable speed controls and foot pedal operation, providing users with enhanced control and efficiency in their work.

Advantages of Using Tube Bead Rollers

Utilizing a tube bead roller brings several advantages to metalworking projects. The primary benefit is the ability to reinforce tube joints, ensuring a secure fit and seal when connecting pipes. This reinforcement is particularly important in systems that channel fluids or gases under pressure. Additionally, the bead rolling process can prevent metal fatigue and failure due to vibration or thermal expansion, which is critical in maintaining the safety and reliability of the tubing systems.

Choosing the Right Tube Bead Roller

When selecting a tube bead roller, it is important to consider the specific requirements of your project. The material of the roller should be compatible with the type of metal tubing you are working with. The size and complexity of the task will determine whether a manual or motorized model is more appropriate. Furthermore, the quality of the roller dies and the range of adjustments available can significantly impact the precision and ease of the bead rolling process.

Maintenance and Care

To ensure the longevity and optimal performance of a tube bead roller, regular maintenance is essential. This includes cleaning the rollers after use, lubricating moving parts, and storing the tool in a dry, dust-free environment. Proper care will not only extend the life of the tool but also guarantee consistent results in the bead rolling process.