(261 products available)

A thermo container liner is a product that is widely used in different industries. Because of this, it is available in various types to cater to different needs. The types include:

Plastic thermo container liners

Plastic thermo container liners are made using different types of plastics. For example, polyethylene and polypropylene. These plastics are lightweight and have a high resistance to impact. The plastic thermo container liners are available in two types, namely; rigid and flexible liners.

The rigid plastic thermo container liners are made to keep the temperature stable for a long time. They are used in applications that require a temperature range that is specific. The flexible liners, on the other hand, are versatile. They are used in applications like food packaging, pharmaceuticals, and chemicals.

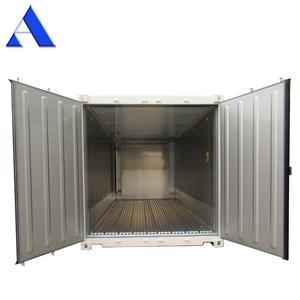

Metal thermo container liners

Metal thermo container liners are mostly made using stainless steel or aluminum. They are durable, corrosion-resistant, and have smooth interiors that are easy to clean. The metal thermo container liners maintain temperatures for a long time and have a high strength-to-weight ratio. They are also recyclable.

Metal thermo container liners provide a modern look, and they are cost-effective. They are popular in industries like food and beverages, industrial containers, and pharmaceuticals.

Composite thermo container liners

Composite thermo container liners combine different types of materials. For example, plastics, metals, and insulation materials. They are designed to provide a combination of benefits of all the materials that are used in their manufacturing. Composite thermo container liners are lightweight and have high thermal efficiency.

They are versatile and provide a long-lasting solution for temperature control. Due to their properties, they are ideal for shipping perishable goods over long distances. Their design minimizes condensation and moisture.

Vacuum-insulated thermo container liners

They are also known as vacuum-sealed thermo container liners. They are made with a vacuum space between the inner and outer walls. The vacuum space reduces heat transfer by conduction and convection. This helps to keep the contents hot or cold for a long time. Vacuum-insulated thermo container liners are popular in high-performance coolers and thermoses.

Foam-insulated thermo container liners

These liners are made using foam insulation. The foam is placed between the inner and outer walls of the container. It is affordable and reduces heat transfer by conduction. Foam-insulated thermo container liners offer good thermal retention at a lower cost. They are commonly used in shipping boxes and medical containers.

Thermo container liners serve vital purposes in temperature control and food safety. Their features make them suitable for transporting various temperature-sensitive items.

Insulation

Insulated thermo container liners maintain the internal temperature of the products. This is important for perishable foods, medicines, and other items that need a specific temperature to remain fresh or be safely transported. The insulation material, such as foam, creates a barrier that reduces heat transfer. This keeps cold items cold and hot items warm.

Lightweight

Thermo container liners are usually made from lightweight materials like plastics and foams. This reduces the overall weight of the container. As a result, this can lower shipping costs, making them more economical for businesses. A lighter container is also easier to handle and transport.

Durability

Thermo container liners are made from robust materials. This includes polyethylene and polypropylene. They can withstand repeated use and rough handling during transportation. Their durability ensures that they provide consistent insulation for many trips. Durable liners also require less frequent replacement, which reduces long-term operating costs.

Customizable sizes

Thermo container liners are available in different sizes and shapes. This includes large bulk sizes and small mini sizes. The liners come in metric or imperial measurements. They can be customized to fit various container sizes, from small boxes to large refrigerated trucks. This ensures optimal insulation regardless of the container's dimensions.

Moisture resistance

Some thermo container liners have moisture-resistant properties. This prevents condensation from forming inside the container. The moisture resistance feature helps to keep the contents dry, especially for products that are sensitive to moisture. It also helps to maintain the quality of perishable items.

Easy to clean

Thermo container liners are made from materials that are easy to clean and sanitize. Some have a smooth, non-porous surface that prevents the buildup of bacteria and pathogens. This is important for businesses in the food industry that must maintain hygienic transport conditions.

Thermo container liners have several applications across different industries and sectors. Here are some common applications:

Food and Beverage Industry:

Thermal container liners are widely used in the food and beverage industry for transporting perishable goods. They help maintain the required temperature during transit, ensuring the freshness and safety of products such as:

Meat and poultry

Dairy products

Fruits and vegetables

Bakery items

Frozen and refrigerated foods

Pharmaceutical and Healthcare:

These liners are crucial in the pharmaceutical industry for the transportation of temperature-sensitive drugs, vaccines, and biological samples. Proper temperature control is essential to maintaining the efficacy and integrity of these products. Additionally, they are used to transport medical supplies, organs for transplantation, and other healthcare materials that require specific temperature conditions.

Cosmetics and Personal Care Products:

Some cosmetics and personal care products are sensitive to temperature and need to be cooled during transportation. This prevents spoilage and maintains their quality. Examples include creams, lotions, and certain fragrance products.

Chemicals and Industrial Products:

Thermal container liners are used in various industries to transport chemicals that must be kept at specific temperatures to prevent reactions or maintain viscosity. This includes lubricants, paints, and certain polymers.

Agriculture:

These liners can be used to transport live animals, fish, and other aquatic organisms at the right temperatures to ensure their health and vitality. Additionally, they help maintain the ideal temperature for agricultural products like seeds and grains during transit.

Electronics:

Some electronic components, such as batteries, may require cooling during transportation to prevent overheating and ensure safety. Thermo container liners can help maintain the necessary temperatures for safe battery transport.

Events and Catering:

Thermal liners are commonly used in event management and catering services to transport hot or cold food items. They ensure that perishable foods and beverages remain at the appropriate temperatures until they are delivered and served.

Retail:

Some retailers use insulated containers with thermal liners for the delivery of groceries, including dairy products, meat, and other perishables. This ensures that customers receive fresh items at the right temperatures.

Purpose

It's vital to determine the liner's intended use before anything else. Is it meant to maintain temperature for beverages, foods, or both? Different applications may require specific materials or designs. For example, a vacuum insulated liner is perfect for beverages, while foam insulated one works well for foods.

Capacity and Size

Consider the desired capacity and size of the thermo container. Container thermos liners come in various sizes, from small to large. The chosen size should correspond to the intended use and the amount of food or liquid that needs to be stored or transported.

Insulation

For products where temperature retention is essential, look for a thermo container liner with excellent insulation properties. Vacuum insulation with double walls is ideal for retaining heat or cold. Also, check if the insulation meets the expected standards.

Material

Thermo container liners are available in different materials, such as stainless steel, plastic, or glass. Stainless steel is durable and resistant to odors and stains, making it a popular choice. Consider the pros and cons of each material before settling on one.

Durability

The thermo container is likely to be used regularly, so choose a liner known for its durability. This is more important for those used for outdoor activities or transportation. Consider options with reinforced parts or those specifically designed for heavy use.

Ease of Cleaning

It's important to maintain hygiene, especially for food-grade liners. Choose a thermo container liner that is easy to clean. This is more important if the liner is used for foods with strong odors or sticky residues. Look for materials that are stain-resistant or dishwasher-safe.

Suction and Sealing

If the thermo container will be used to transport liquids, it's important to choose a liner with a secure lid and a tight seal. This will help prevent leaks and spills. Consider options with silicone seals or locking mechanisms for added security during transportation.

Design and Aesthetics

While functionality is key, the design and appearance of the thermo container should not be overlooked. Choose a liner with a design and finish that meets the intended market preferences. Some designs may offer better grip or easier pouring.

Compatibility

Ensure that the thermo container liner is compatible with the outer shell and other components. This will ensure optimal performance and avoid any issues during the manufacturing process. Consider working closely with suppliers to determine the best configurations.

Q1: What are the benefits of metal thermo container liner?

A1: Metal liner is durable, robust, and resistant to high temperature. It can withstand rough handling and is ideal for heavy-duty use. Metal retains heat better than other materials, keeping food warm for longer. It is easy to clean and maintain, providing good hygiene.

Q2: What are the disadvantages of a metal thermo liner?

A2: Metal can react with acidic foods, altering the taste and potentially causing harm. It is heavier than other materials, making the container more difficult to carry. Some metals may rust if not properly cared for. Metal does not provide the best insulation compared to other materials.

Q3: What are the types of metals used as thermo container liners?

A3: Stainless steel and aluminum are the most common metals used. Stainless steel is popular due to its durability, resistance to rust, and ability to retain heat. Aluminum is lightweight and conducts heat well, making it a good choice for containers that need to keep food warm or cool.

Q4: What should retailers consider when sourcing thermo container liners?

A4: They should consider the type of insulation used, durability and materials of the liners, and the design and capacity of the containers. Retailers should also pay attention to the brand's reputation and customer reviews. This will help them to select high-quality products that meet the needs of their customers.