Popular in your industry

Related Searches:

Top categories

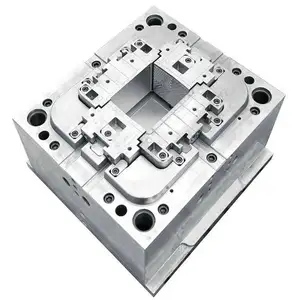

About plastic tray injection molding machine

Introduction to Plastic Tray Injection Molding Machines

Plastic tray injection molding machines are pivotal in the manufacturing sector, serving as the backbone for producing versatile plastic trays used across various industries. These machines are engineered for efficiency, ensuring a seamless production process from raw plastic granules to finished products.

Types and Applications

The range of plastic tray injection molding machines includes various models tailored to meet diverse industry requirements. These machines are not just limited to creating simple trays; they are also adept at manufacturing intricate PVC pipe fittings, making them indispensable in the packaging industry for products like thin wall containers, caps, pails, and buckets.

Technical Features and Materials

A plastic injection molding machine is equipped with a specialized screw that enhances plasticizing shot weight and speed, ensuring efficient production. The robust clamping force, which varies between machines, is designed to withstand external machining forces, maintaining the integrity of the mold under high-pressure conditions. The construction of these machines often involves the use of durable steel for components like the steel bush in the clamping unit, which is optimized to minimize wear resistance.

Advantages of Using Advanced Molding Machines

Investing in a plastic tray injection molder brings several advantages. The precision of these machines leads to reduced defective rates, and the single-cylinder system with a servo-valve ensures a consistent response rate during operation. Furthermore, the design improvements in these machines contribute to their long service life and reliability.

Innovations in Machine Design

The latest injection molding equipment showcases continuous design enhancements for high-speed operations. Innovations include multi-select applications, allowing for flexibility in production. The new structure of the steel bush in the clamping unit is a testament to the evolution in design, reducing lubrication costs and enhancing the machine's overall efficiency.

Choosing the Right Machine for Your Needs

Selecting the appropriate plastic injection moulding machine is crucial for your business's success. The machines available on Alibaba.com cater to a wide range of production needs, from small-scale operations to large industrial tasks. With detailed descriptions and specifications, buyers can find the machine that aligns with their production volume and technical requirements.