Popular in your industry

Related Searches:

Top categories

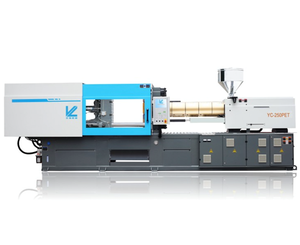

About plastic injection moulding machine

A plastic injection moulding machine is a mechanical device designed to manufacture plastic products and components. It is an integral part of the plastic injection moulding process, which involves melting plastic material and injecting it into a mould to produce a wide range of items, from intricate parts to larger objects. The machine is equipped with various components, including a barrel, a hopper, an injection unit, a clamping unit, and a control panel, all working in synchronization to ensure precise and efficient production.

Types of plastic injection moulding machines

There are distinct types of plastic injection moulding machines, each tailored to specific production needs. Hydraulic plastic injection moulding machines leverage hydraulic systems to generate the pressure required for the injection process. These machines are known for their ability to handle high pressures, making them suitable for manufacturing larger and more complex plastic components. On the other hand, electric plastic injection moulding machines use electric motors to power the machine's various functions. They are recognized for their energy efficiency, precise control, and fast cycle times. Hybrid plastic injection moulding machines combine the features of both hydraulic and electric machines, offering a balance between power and energy efficiency. These machines often incorporate electric drive for the plasticizing and clamping functions while using hydraulic systems for injection.

Applications of plastic injection moulding machines

Plastic injection moulding machines are pivotal in the production of a vast array of plastic products across numerous industries. In the automotive sector, these machines fabricate intricate components such as dashboards, bumpers, and interior trim. They are also pivotal in the manufacturing of medical devices and equipment, ensuring the production of sterile and precise items. Plastic injection moulding machines are crucial in the production of consumer goods, including home appliances, electronic enclosures, and packaging. They are common in the construction industry for making pipes, fittings, and insulation components. Additionally, the machinery industry, plastic injection moulding machines contribute to producing various components for machinery and equipment.

Features of a plastic injection moulding machine

Plastic injection moulding machines are constructed with a myriad of features to ensure optimal performance and efficient production. They are typically equipped with advanced control panels and software that allow operators to monitor and adjust various parameters such as temperature, pressure, and cycle times. Many modern machines incorporate automation and robotics to streamline processes and enhance overall productivity. A notable feature is the ability to handle a wide range of thermoplastics, offering versatility in manufacturing different types of components. Machine designs may vary, with some catering to high-speed production and others focusing on precision and repeatability. To ensure safety in the workplace, plastic injection moulding machines are often equipped with safety measures, such as interlocking gates, emergency stop buttons, and protective shields.