Popular in your industry

Related Searches:

Top categories

About plastic flake making machine

What is Plastic Flake Manufacturing Machine

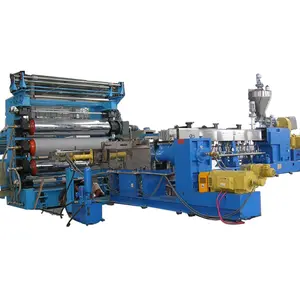

Plastic flake manufacturing machines are innovative solutions designed for the production of plastic flakes, a common raw material in various industries. These machines serve as a key component in the plastic recycling process, offering a cost-effective and environmentally friendly way to transform post-consumer or industrial plastic waste into reusable flakes. The flakes can then be used in the manufacturing of new plastic products, creating a closed loop of production and consumption that is beneficial for both businesses and the planet.

The target audience for plastic flake manufacturing machines includes businesses involved in plastic recycling, manufacturers who require recycled plastic as a raw material, and even entrepreneurs looking to start their own plastic flake production facilities. These machines are particularly suitable for companies seeking to reduce their environmental footprint by reusing plastics that would otherwise end up in landfills.

Plastic flake manufacturing machines work on the principle of size reduction and are often part of a larger production line that includes processes such as shredding, washing, and drying. The first step in the process is the shredding of plastic materials into small pieces. These pieces are then washed to remove contaminants and excess material. After washing, the plastic is further reduced in size and sometimes subjected to additional treatments like drying or color sorting. The end result is high-quality recycled plastic flake that can be used in the production of new plastic items.

Types of Plastic Flake Manufacturing Machine

The types of plastic flake manufacturing machines available cater to a spectrum of needs within the industry. Here are some common variations:

-

PET Bottle Flakes Recycling Machine: This machine is specifically designed to recycle PET (polyethylene terephthalate) flakes, which are widely used in the production of beverage bottles and food packaging due to their clarity and strength. They can be reprocessed into items such as textiles or automotive parts.

-

HDPE/PP Bottle Flakes Recycling Machine: HDPE (high-density polyethylene) and PP (polypropylene) flakes are often used in the manufacturing of milk jugs, yogurt containers, and other rigid packaging. The machines that handle these materials must be capable of dealing with their varying densities and sizes.

-

PE/PP Film Flake Recycling Machine: For recycling plastic films, these machines are equipped to handle both pre-consumer and post-consumer waste from items like shopping bags, packaging material, and agricultural films. They can produce high-quality flake suitable for use in various plastic products.

-

PS Foam Flake Recycling Machine: This type is dedicated to processing PS (polystyrene) foam waste, commonly found in packaging material and insulation. The resulting flakes can be used in the production of more PS products or recycled into other goods.

How to choose Plastic Flake Manufacturing Machine

Selecting the right plastic flake manufacturing machine is crucial for businesses aiming to produce high-quality recycled materials. When considering a purchase on Alibaba.com, it's important to assess several factors:

-

Capacity and Output Quality: Evaluate the quantity of flakes needed and the quality required for your specific application. Higher-capacity machines will allow you to process more material but may require more space and energy.

-

Material Compatibility: Check the types of plastics that can be effectively processed by the machine. Some machines are designed for specific materials like PET or HDPE, while others can handle a variety of inputs.

-

Energy Efficiency: Consider the energy consumption of the machine, especially if you're operating in an area with high utility costs. Newer models often offer improved energy efficiency.

-

Maintenance Requirements: Look for machines designed with easy maintenance in mind. This will reduce downtime and ensure that the equipment operates efficiently.

-

Technical Support and After-Sales Service: Given that these are complex machines with critical operational needs, technical support and after-sales services should be prioritized.

By weighing these considerations against your specific needs and budget constraints, you can make an informed decision when choosing a plastic flake manufacturing machine on Alibaba.com.

About Plastic Flake Manufacturing Machine on Alibaba.com

Alibaba.com stands out as an expansive marketplace that caters to businesses worldwide seeking reliable suppliers of plastic flake manufacturing machines. With an extensive array of options available on the platform from numerous suppliers across different regions, Alibaba.com facilitates an efficient procurement process tailored to commercial needs. The platform's commitment to connecting businesses with high-quality industrial equipment ensures that you can find suitable plastic flake manufacturing machines whether you operate on a small scale or require large-scale production capabilities.

Alibaba.com's user-friendly interface simplifies the search for specific types of plastic flake manufacturing machines by allowing you to filter results based on core components, local service locations, plastic processed, and even key selling points like productivity levels or ease of operation. Moreover, Alibaba.com provides services such as Trade Assurance which protects your payments until delivery is confirmed, offering peace of mind during transactions.

The platform’s global reach means that no matter where your business is located, you have access to a vast selection of suppliers who can meet your specifications – whether you need a machine that can handle different plastic types or one that offers high productivity levels without compromising on quality. This variety makes Alibaba.com an indispensable resource for businesses looking to stay competitive in the ever-evolving plastic recycling industry.

Common FAQs for Plastic Flake Manufacturing Machine

What are the main types of plastic flake produced by your machines?

Our machines primarily produce PP (Polypropylene), HDPE (High-Density Polyethylene), PE (Polyethylene), ABS (Acrylonitrile Butadiene Styrene), and PC (Polycarbonate) flakes.

What should I consider when choosing a plastic flake manufacturing machine for my recycling business?

Consider the types of plastics you will be processing, the desired flake size and quality, the machine's energy consumption, its production capacity, and the after-sales support available.

Can the plastic flake manufacturing machines handle different plastic materials?

Yes, most plastic flake manufacturing machines are versatile and can handle a variety of plastic materials, including PP, HDPE, PE, ABS, PC, and more.

How does the choice of machine affect the quality of the produced flakes?

The machine's design and core components such as the screw and gearbox directly impact the quality of the produced flakes; hence it's essential to select a machine that meets your specific application needs.

Are there any maintenance requirements for plastic flake manufacturing machines?

Yes, regular maintenance is required to ensure the machine operates efficiently. This includes checking for wear on parts, ensuring proper lubrication for moving components, and monitoring the cooling systems.

Can plastic flake manufacturing machines be integrated into existing production lines?

Many plastic flake manufacturing machines are designed to be easily integrated into existing production lines or used as standalone units, depending on their configuration and production scale.

What industry standards should I look for when purchasing a plastic flake manufacturing machine?

Look for machines that adhere to recognized industry standards for safety and quality, such as CE or UL certifications, which ensure they meet regulatory requirements.

How do I ensure compliance with local regulations when using a plastic flake manufacturing machine?

Ensure that the machine's design and operation comply with local safety and environmental regulations. It may also be helpful to verify that your chosen machine has a machinery test report and operates within the relevant industry guidelines.

What after-sales services are typically offered with the purchase of a plastic flake manufacturing machine?

After-sales services may include video technical support, online support, field maintenance and repair services, and in some cases, engineers available to service machinery overseas.

Do plastic flake manufacturing machines come with training for operation and maintenance?

While Alibaba.com does not directly provide training services, some suppliers may offer manuals or online resources that provide guidance on operating and maintaining your purchased equipment.

How does Alibaba.com ensure the quality of plastic flake manufacturing machines sold on its platform?

Alibaba.com facilitates connections between buyers and suppliers around the world and offers services like Trade Assurance to help protect your transactions and ensure you receive the quality of equipment you paid for.