The mould grinding machine is a vital instrument in the realm of precision manufacturing, engineered to sculpt and perfect moulds with exceptional accuracy. These apparatuses are pivotal in sectors where crafting intricate and exact moulds is a regular imperative. A mould grinding machine boasts the versatility to manage diverse materials and intricate configurations, guaranteeing that the resultant moulds adhere to exacting quality benchmarks.

Types and Applications of Mould Grinding Machines

Within the sphere of mould grinding machines, a variety of models exist, each distinguished by its specialized features. The moulder knife grinder is specifically designed for the woodworking industry, honing knives with precision to forge elaborate patterns and motifs. The universal cutter bit sharpener grinder, known for its adaptability, can accommodate a range of cutting implements, rendering it indispensable in tool rooms and broader manufacturing settings. These devices are not merely crucial for woodworking but also for the metalworking and plastics industries, where precision moulds are essential for large-scale production. Each grinder is crafted with particular industrial needs in mind, ensuring a match between the machine's capabilities and the precision and efficiency requirements of its users.

Structure and Features of Mould Grinding Machines

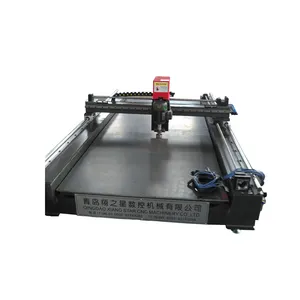

The architecture of a mould grinding machine reflects a commitment to engineering exactitude, comprising a robust base that anchors dynamic elements such as the grinding wheel, motor, and control panel. The grinding wheel, the machine's core, is where the mould-shaping action occurs. Typically composed of hard-wearing abrasive materials, it can tackle metal, wood, or plastic. The motor energizes the grinding wheel, with its power output being a key determinant of the machine's efficacy. The control panel enables operators to tailor grinding parameters, including speed and depth, to the unique specifications of each mould. This harmonious integration of components yields a machine that operates with unwavering precision and dependability.

Materials and Durability

The construction of mould grinding machines employs materials chosen for their endurance and functional performance. Frames are often crafted from premium-grade steel, providing the structural fortitude necessary for the machine's operations. Grinding wheels typically consist of a blend of industrial diamonds or other hardy abrasives, selected not only for their longevity but also for their consistent precision over time, a critical factor in the production of uniform, high-caliber moulds.

Business Usages and Key Selling Points

In the commercial sphere, the mould grinding machine is foundational to the fabrication of superior moulds. Its utility spans a multitude of industries, from automotive—where exact moulds are crucial for component production—to toy manufacturing, where detail and uniformity are paramount. In the aerospace sector, the precision these machines provide is instrumental to the safety and functionality of aircraft components. The ability of these machines to rapidly and precisely produce moulds adds considerable business value, curtailing lead times and enhancing production rates without compromising on quality.

Functions and Capabilities

The principal role of a mould grinding machine is to grind and contour moulds to precise dimensions. It is adept at executing tasks such as surface grinding, cylindrical grinding, and intricate contouring. Designed to accommodate a spectrum of materials, from pliable plastics to hardened metals, the machine can be tailored to meet the demands of virtually any manufacturing process.

Features and Unique Selling Points

What distinguishes a mould grinding machine from other industrial machinery is its unparalleled precision and adaptability. Attributes such as programmable controls, automatic tool changers, and cooling systems to mitigate overheating are among its unique selling propositions. These features enable sustained operation, maintenance of strict tolerances, and the production of moulds that conform to precise industry standards.

Benefits and Advantages for Industries

The advantages of deploying a mould grinding machine in industrial environments are multifold. They deliver a high degree of precision, ensuring each mould is an exact duplicate of its predecessor, which is vital for mass production. The machines' efficiency reduces both material waste and energy consumption, leading to cost savings and a lesser environmental footprint. Moreover, the capacity to fabricate complex moulds in-house can substantially diminish the time and expense associated with external procurement.

How to Choose the Right Mould Grinding Machine

Selecting the appropriate mould grinding machine entails evaluating your business's specific requirements. Factors to consider include the types of materials to be processed, the intricacy of the moulds, and the production volume. It is also crucial to assess the machine's power, precision, and the availability of after-sales support. A comprehensive understanding of these elements will steer you towards a machine that aligns with your operational needs.

How to Maintain Your Mould Grinding Machine?

Proper maintenance of a mould grinding machine is essential to preserve its longevity and operational efficacy. Routine upkeep involves cleansing the apparatus to eliminate any detritus that could impede its function, inspecting the grinding wheel for wear, and ensuring all moving parts are adequately lubricated. Periodic servicing should encompass evaluations of the electrical system, structural integrity, and the precision of the controls.

What are the local service locations for mould grinding machines?

For enterprises in need of local support, mould grinding machines benefit from a network of service locations across the globe, including Russia, India, Malaysia, Vietnam, Indonesia, Canada, the United States, Australia, Thailand, and Germany. This international presence guarantees that users have ready access to maintenance and parts replacement, minimizing operational interruptions.

What are the key selling points for businesses considering a mould grinding machine?

Enterprises contemplating the acquisition of a mould grinding machine should concentrate on pivotal selling points such as user-friendly operation, competitive pricing, and the potential for elevated productivity. Furthermore, the machines' multifunctional capabilities allow for a wider scope of applications, rendering them a versatile asset to any workshop.

How does a mould grinding machine contribute to manufacturing efficiency?

A mould grinding machine bolsters manufacturing efficiency by supplying moulds of high accuracy that minimize waste and seamlessly integrate into the production line. Its energy-efficient features and extended service life reduce operational expenses, while its multifunctional nature permits the completion of various tasks with a single piece of equipment.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4