(1196 products available)

Mini grain loaders are essential pieces of machinery used primarily in the agricultural sector. Several types of loaders exist, each purpose-built for various types of grain and loading situations. Their functionality is primarily designed to simplify the transfer process from one point to another, whether for loading or offloading purposes.

Mini grain loaders can generally be categorized according to the type of grain they are designed for, the mechanism they employ, and their portability.

While the types of mini loaders may vary according to all these factors, it is worth mentioning that some have recently emerged.

Mini loaders have several unique specifications that set them apart in the market and indicate what applications they will suit best.

Dimensions

The dimensions of the mini loader indicate the overall size and weight of the equipment, which can affect its capacity and maneuverability. The average weight seems to vary between models, but they are all under three tons, which makes it easy to transport on a trailer or truck to any location.

Engine Power

This specification indicates what type of engine power will drive the grain loader. It usually shows a horsepower or kilowatt range that is sufficient to operate various machinery and manage different loads. The fuel type also varies and can be electricity, gas, gasoline, diesel, or propane.

Lifting Capacity

The lifting capacity of the loader will be specified in kilograms. It indicates the maximum weight the loader can lift and transport safely. Knowing the lifting capacity is crucial when deciding what type of material and load can be handled by the equipment. It usually ranges between 500 kg and 1500 kg.

Lift Height

This is the maximum height at which the loader can lift materials. The lift height is closely associated with the type of boom used in the machine. This specification is important because it indicates the highest loading or stacking levels that can be attained. The average lift height seems to range between two and four meters.

Operating Weight

The operating weight of the loader is basically the same as its gross weight. It includes the weight of the machine as well as any additional load it may carry. This operating weight affects the stability and maneuverability of the machine when it moves, lifts, and transports materials.

Max Torque

Mini grain loaders and all loaders have a motor power and torque setting that indicates its rotational power. Torque is responsible for producing the thrust needed to move heavy objects and materials. Higher torque motors are capable of handling and moving denser and heavier materials.

Transmission

This includes type and gears. In many loaders, a hydrostatic transmission system is used to facilitate the movement of heavy loads at varying speeds. The gears seem to have one or two speeds on average.

Fuel Capacity

The fuel capacity is the amount of fuel the mini grain loader can store to operate its engine and power its hydraulic system. Operating weight affects how much fuel is consumed to drive the machine.

Tires or Tracks

Tires will have to be specified whether they are of a solid or inflated material and their size. A mini grain track loader will have a rubber track dimension instead. The size will impact the stability and ground traction of the loader.

Attachment

Grain mini loaders use different types of attachments based on the functionality or task that needs to be performed. Some of them are buckets, pallet forks, augers, and excavator attachments. Each attachment is designed to complement a specific application.

Regular maintenance helps keep the mini grain loaders running smoothly for years. Here are some tips:

The use of mini grain loader has grown in the recent past due to its flexibility and usefulness in loading and unloading grain and other similar products. It is not only confined to agriculture but has found use in various industries and sectors. Here are some common applications where mini grain loaders are used.

Farming and agriculture

Mini grain loaders are extremely helpful in the farming and agriculture industry. It is used to load crops like rice, wheat, pulses, etc., from farms into trucks, trailers, or containers for transportation to markets or storage facilities. Such loaders are also used to unload crops from vehicles to silos, warehouses, or processing units. Mini loaders of all sorts are ideal for off-loading grain from ships at the port onto trucks for further transportation. They are also essential for farm operations like harvesting, grain cleaning and sorting, and livestock feed.

Food processing

The food processing industry uses mini grain loaders for various tasks. These include transporting raw materials like grains, seeds, and legumes from storage facilities or silos to production lines, mills, or processing units. Grain loaders are also used to off-load processed food and pack it in storage units for later use or distribution. Grain loaders are vital for bagging and packaging grain-based food products like flour, cereals, snacks, and other items. They help increase productivity and streamline operations.

Fertilizer and chemical production

In this industry, mini grain loaders are used to move raw materials like grains, meals, and other solid additives from storage to mixing or processing units. Once the process is complete, the final product is off-loaded and stored with the help of a grain loader. These machines can also be used to load fertilizers onto tractors or trucks for transportation to fields or gardens.

Livestock ranches and farms

Mini grain loaders are a convenient way to transport feed to livestock farms. Animals like poultry, cattle, and pigs require a specific diet to grow and give produce. Grain loaders are used to transport those specific feeds from storage facilities to the animals. They are also used to load grains and feed from storage systems, hoppers, or silos into mixers, feeders, or livestock pens.

Construction

In the construction industry, mini grain loaders can be used for multiple tasks, such as loading or unloading aggregates, sand, gravel, cement, or other bulk materials. Mini loaders are perfect for off-loading heavy material from ships at the port and transporting them to construction sites with ease.

Logistics and warehousing

Logistics and warehousing facilities use grain loaders for loading and unloading goods to be stored or dispatched. They help in efficiently storing products in silos or warehouses. Their compact size means they can maneuver through tight spaces and aisles with ease.

Ports and maritime

Mini grain loaders are helpful when dealing with bulk solid products like grains, seeds, and cereals at ports. They can be easily moved around shipping containers and vessels and are critical for transshipping goods from ships to trucks or storage containers.

Retail and e-commerce fulfillment

In the retail industry, mini grain loaders help to pack products on shelves and ensure that stock is not finished. They are also useful to load packing belts or boxes with grain-based products.

When choosing proper mini grain loaders for sale, it is necessary to attract customers looking for suitable loaders for their farms. Therefore, the following tips focus more on customers' needs.

Suitable Grain Bin Diameter

When selecting small grain loaders, one should consider the suitable grain bin diameter they can handle. Different mini loaders work well with specific grain bin diameters. Mini loaders are commonly designed for grain bins with 12' to 24' diameters. For example, some loaders are designed to work with a grain bin having a 18-foot diameter and a 16-inch tube. Such loaders would not be suitable for grain bins with different dimensions. Therefore, it is important to choose mini grain loaders that have been designed for a specific grain bin diameter.

Power Source

Typically, mini grain loaders are powered by either a gasoline engine, a standard 230-volt electric motor, or a diesel engine. Choosing a suitable power choice ensures smooth and effective operation. Grain bin loaders powered by an electric motor offer the advantage of eliminating engine exhaust while operating. Nevertheless, selecting the proper power source will depend on the customer's need.

Speed and Capacity

An average mini grain loader has various capacities ranging from 3,500 bushels per hour to 10,000 bushels per hour. Grain farmers prefer loaders with higher capacities and speeds to minimize loading time during harvest. However, one should note that capacity and speed vary depending on the engine's power source, design, and functionality. When choosing grain loaders, it is essential to consider the speed and capacity that customers prefer during grain harvesting.

Design

Apart from the above important factors, it would help to choose loaders with unique designs. Most farmers prefer grain loaders designed for easy integration with various types of unloading equipment. Some have a collapsible design that facilitates easy transportation and storage. Choosing loaders with unique designs will definitely satisfy different farmer's preferences.

Q1. Are mini loaders worth it?

A1. They are worth it because they can save costs by reducing manual labor, increasing efficiency, and minimizing product loss during loading.

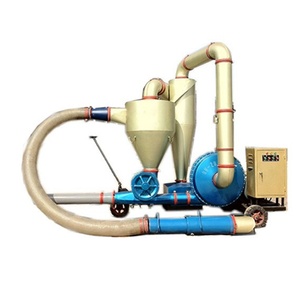

Q2. What types of grain loaders are there?

A2. There are four main types of loaders: belt loaders, auger loaders, gravity wagon loaders, and air slip loaders. Each has its mechanism and advantages for specific grain loading tasks.

Q3. How fast does a grain loader work?

A3. The speed of grain loaders can vary significantly depending on the type and model. Mini grain loaders can move 300 to 800 bushels per hour, while larger loaders can load up to 4,000 bushels per hour.

Q4. What maintenance does a mini grain loader require?

A4. Regular inspections, lubrication of moving parts, checking for belt or auger wear, cleaning, and timely repair to prevent any major breakdowns are usual maintenance for grain loaders.