Popular in your industry

Related Searches:

Top categories

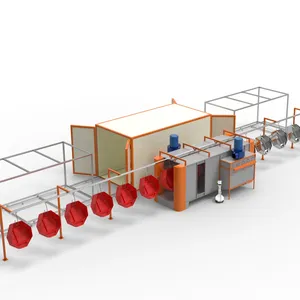

About large powder coating oven

A powder coating oven is a vital piece of equipment in the powder coating process. This process is a popular technique for adding surface coatings to materials such as metals, ceramics, plastics, and more. The primary purpose of powder coating is to enhance protection, aesthetics, and durability. It shields materials from atmospheric influences. Whether users require a small powder coating oven, a large powder coating oven, a gas powder coating oven, or an electric variant, an extensive range of powder coating ovens are on offer.

The working principles of powder coating ovens

The working principles of a powder coating oven are rooted in the application of heat to the coated substrate. This heat application ensures the powder adheres firmly, resulting in a smooth and long-lasting finish. Specialized ovens are necessary to avoid direct contact between the heating elements and the coating. Powder coating booths and ovens use heating coils for convection heating, which evenly distributes heat without making contact with the coated object. Precise temperature settings and a timer are used in a powder coating oven to regulate the curing process, enabling the powder to form a durable film on the metal. The volumetric capacity of the oven is crucial, especially in industries like automotive, where large components need uniform curing conditions.

The operating process of powder coating ovens

The operation of a powder coating oven involves several critical steps. First, a uniform layer of powder coating is applied to the surface of the object. This is often achieved using electrostatic spraying or an electrostatic gun, ensuring that the powder adheres to the object's surface. Preheating within the powder coating oven promotes the adhesion and uniform flow of the powder. This step facilitates the powder to adhere and flow correctly, resulting in an even coating. The final step is baking and curing. Objects are baked at high temperatures, typically around 450°F, in the powder coating oven to melt and cure the powder coating, forming a robust surface coating.

Importance of vents in powder coating ovens

A vent is often necessary for a powder coating oven to function correctly and to ensure a safe working environment. During the powder coating process, the powder material is melted and cured, releasing volatile organic chemicals and other potentially harmful gases. Without adequate ventilation, these gases can accumulate in the workplace, posing a fire threat or a health risk to personnel. A vent system can help eliminate harmful gases and maintain a safe workspace. A vent system also aids in controlling the temperature and humidity inside the oven, ensuring consistent and top-notch powder coating results. Therefore, every powder coating oven, especially larger models like an industrial powder coating oven, must have a well-planned and constructed ventilation system.