Popular in your industry

Related Searches:

Top categories

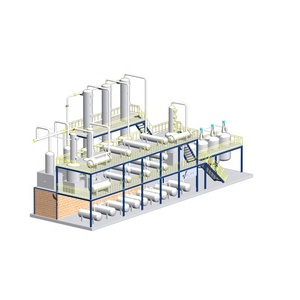

About industrial oil refining machine

Industrial oil refining machines are essential equipment in the oil industry used to process crude oil into valuable products. An oil refinery machine employs various processes to remove impurities and enhance the quality of oils, making them suitable for consumption or further use in various applications. Oil refining machines play a crucial role in producing high-quality oils by refining different types of oils, such as palm oil, soybean oil, and sunflower oil. They are commonly used in refineries to meet the growing demand for refined oils in the global market.

Types of industrial oil refining machines

There are various types of industrial oil refining machines available, each catering to specific refining needs. A small oil refinery machine is ideal for small-scale refining operations, making it suitable for small oil producers or entrepreneurs. This type of machine is compact, cost-effective, and designed to refine a limited quantity of oil. Additionally, a edible oil refinery machine is specifically designed for refining edible oils, such as vegetable oils, to make them safe for consumption. It removes impurities, odors, and undesirable components, ensuring the final product meets food safety standards. Large-scale industrial oil refining machines are equipped with advanced technologies and automation features to handle bulk oil refining operations efficiently.

The working principle of an industrial oil refining machine

The working principle of an industrial oil refining machine involves several key processes that are crucial for refining crude oil. The first step is degumming, where the machine removes gums and impurities from the oil. This process is essential for improving the oil's quality and stability. The next step is neutralization, where the machine uses chemicals to neutralize free fatty acids and remove other impurities. Subsequently, the oil is heated to remove moisture and volatile compounds in the deodorization process, improving the oil's taste and odor. Moreover, the industrial oil refining machine undergoes the final step of filtration to remove any remaining impurities, resulting in a refined, high-quality oil ready for consumption or further processing.

The advantages of an industrial oil refining machine

An industrial oil refining machine offers several advantages, making it an indispensable tool in the oil refining industry. First, it enhances the oil's quality by removing impurities, odors, and undesirable components, resulting in a clean and refined final product. Second, it improves the oil's stability and shelf life, ensuring it can be stored for extended periods without degradation. Third, an oil refinery machine allows for the customization of refining processes to meet specific quality standards and market demands. This flexibility is crucial for producing a wide range of high-quality oils. Fourth, the machine is cost-effective, offering efficient and consistent refining results, reducing production costs in the long run. Lastly, it increases the overall production capacity by streamlining the refining process and ensuring consistent output, meeting the demands of a growing market.