(103290 products available)

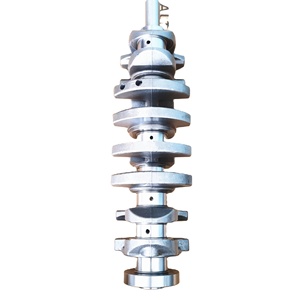

A engine crankshaft is an essential part of any rotating shaft that converts the pistons' up-and-down motion into a rotational motion. The crankshaft is significant in the engine block, which contains most of the engine's parts. The engine crankshaft comes in various sizes and shapes, which differ depending on the model of the engine. Below are some of the most common types of crankshafts.

Cast iron crankshafts:

This is the most widely used type of crankshaft. It is widely used because, despite being the cheapest, it is durable and corrosion-resistant. A cast iron engine crankshaft has a high carbon content that makes it strong and hard. The cast iron crankshaft is suitable for high-speed engines, but it is heavier and not ideal for racing engines. The cast iron crankshaft is easy to manufacture, and this, coupled with its mechanical properties, makes it a popular choice for many engine models.

Steel crankshafts:

Steel is a strong and tough material that is widely used in manufacturing various mechanical engine parts. Steel crankshafts have high tensile strength and are suitable for heavy-duty applications. Steel crankshafts are also resistant to wear and damage, making them long-lasting. Compared to cast iron crankshafts, steel crankshafts are more flexible and have better strength. The steel crankshaft is widely used in diesel engines and other heavy-duty engines.

Forged steel crankshafts:

Forged steel crank shafts are manufactured using a forging process. In this process, a solid steel billet is heated to a high temperature and then shaped into the desired crankshaft shape using a hammer. This manufacturing process results in a crankshaft with a uniform and refined grain structure, which means that the crankshaft has better mechanical properties. Compared to crankshafts of other materials, forged steel crankshafts have better strength, durability, and resistance to fatigue. The only disadvantage of forged steel crankshafts is the high manufacturing cost, which makes this crankshaft suitable for applications that require high performance, such as in racing cars.

Aluminum alloy crankshafts:

Aluminum alloys are known for their light weight and excellent corrosion resistance. These features make aluminum alloy crankshafts suitable for applications where lightweight components are critical, such as in racing cars and high-performance engines. The mechanical properties of aluminum alloy crankshafts can be improved by adding small amounts of other elements, such as copper, magnesium, and silicon, to achieve better strength and durability.

The specifications of an engine crankshaft have a great deal of influence on the engine's performance. Here are a few key specifications:

Regular maintenance is important to keep the engine crankshaft working well and to prolong its lifespan. Here are some simple ways to maintain the crankshaft:

When buying a engine crankshaft, buyers should consider the following factors.

Consider the Engine Configuration

When choosing a crankshaft for an engine, the engine's configuration is vital. This is because the engine's configuration determines the crankshaft design. For example, V-shaped and inline crankshafts have different designs. Considering the engine configuration helps in choosing a crankshaft that fits into the engine.

Determine Stroke Length and Crankpin Diameter

Buyers should consider the stroke length and crankpin diameter. This is because the stroke length affects the engine's power output. A longer stroke generates more power. The crankpin diameter connects the crankshaft to the engine's connecting rod. Buyers should choose a crankshaft with a stroke length and crankpin diameter that fits into the engine.

Understand Balance and Vibration Considerations

Buyers should choose a crankshaft that balances the engine. An unbalanced crankshaft causes engine vibration and damages engine parts. An engine crankshaft with a balance mechanism prevents engine vibration.

Budget and Performance Goals

Buyers should consider their budgets when buying a crankshaft. Crankshafts for high performance are quite expensive. Also, buyers should choose a crankshaft that meets their engine performance goals.

Material and Construction

Buyers should choose a crankshaft with a material and construction suitable for their engine design. Cast iron and steel are ideal for small engines. On the other hand, large and high-performance engines require forged steel crankshafts. This is because the forged steel crankshaft can withstand high stress and pressure.

Replacing a crankshaft can be a daunting task, but with the right tools and mechanical knowledge, it can be done. To replace a crankshaft:

Preparation

Disconnect the battery, drain the engine oil and coolant, and lift the vehicle.

Remove the Engine

Start by removing the engine from the vehicle. This involves disconnecting various components like the exhaust, intake, electrical connections, and cooling system. After that, the engine is supported with an engine stand, and the engine is lifted from the vehicle.

Disassemble the Engine

The engine is disassembled with the help of an engine manual, which gives details about the disassembly process. After that, the crankshaft is accessible after removing the oil pan, timing cover, and other components that obstruct its access.

Remove the Old Crankshaft

The old crankshaft is removed with a crankshaft pulley, which is removed with a puller. After that, the main bearing caps are removed, and the crankshaft is slid out of the engine block.

Install the New Crankshaft

Before installing a new crankshaft, it is important to ensure it is cleaned and lubricated. After that, the new crankshaft is slid into the engine block, and the main bearing caps are torqued to specifications. Also, ensure the crankshaft pulley is installed.

Reassemble the Engine

After the crankshaft is replaced, the engine is reassembled and mounted back into the vehicle. All the disconnected components are reconnected, and the fluid is filled to the required levels.

Q1: What is an engine crankshaft?

A1: The engine crankshaft is a key part of the car's engine that turns the up-and-down movements of the pistons into rotating power. This spinning is what makes the car able to drive forward or backward.

Q2: Where is the crankshaft located in the engine? Crankshafts are located in the engine block and are accessible only by removing the engine's oil pan and the flywheel or flexplate attached to the crankshaft's back.

Q3: What is the difference between a forged and a cast crankshaft? A3: Forged crankshafts are made from solid metal, making them very tough for high-power engines. Cast crankshafts are molded from liquid metal, which is cheaper and sufficient for most regular car engines.

Q4: How do you maintain a crankshaft? A4: Proper lubrication, avoiding overloading in case of crankshaft used in generator, and regular inspection are key to maintaining it. Using good quality engine oil and regular oil changes keep it smooth.

Q5: What happens if the crankshaft is damaged? A5: If the crankshaft is damaged, the engine's ability to turn power smoothly will be disrupted, causing shaking and uneven power. This could make the car sluggish and eventually stop running if not fixed.