Popular in your industry

Related Searches:

Top categories

About desma shoe mould

Introduction to Desma Shoe Moulds

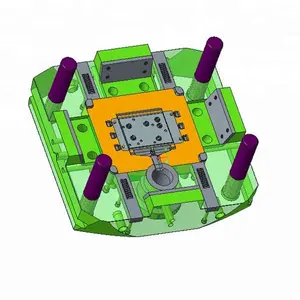

Desma shoe moulds are specialized tools used in the footwear industry to shape and create a variety of shoe designs. These moulds are essential for manufacturers looking to produce shoes with precision and consistency. A desma shoe mould is crafted to meet the specific requirements of shoe production, ensuring that each pair of shoes maintains the same standard of quality and fit.

Types and Applications

There are various types of desma shoe moulds available, each serving a different purpose in the shoe manufacturing process. From single-color to multi-color moulds, they cater to a diverse range of shoe designs and styles. The application of these moulds extends from creating the sole of the shoe to forming the intricate details on the upper part. They are indispensable in the production of sports shoes, formal footwear, and casual shoes alike.

Features and Materials

Desma shoe moulds are known for their robust features, including durability and precision in design. The materials used in the construction of these moulds, such as aluminum and steel, are selected for their longevity and ability to withstand the high pressures of injection molding. The design intricacies of these moulds allow for a high level of detail in the final shoe product, which is crucial for both aesthetic appeal and functional design.

Advantages of Using Desma Shoe Moulds

Utilizing desma shoe moulds in production offers numerous advantages. These moulds provide a consistent quality in shoe production, which is vital for maintaining brand reputation. They also allow for a high degree of customization, enabling manufacturers to produce shoes that meet specific market demands. Additionally, the use of these moulds can lead to increased efficiency in the manufacturing process, potentially reducing production time and costs.

Optimizing Production with Desma Shoe Moulds

Manufacturers can optimize their production processes by incorporating standardized elements into their desma shoe moulds. Standardizing components such as lift bars, connection sizes, and clamp slots can simplify the manufacturing process, making moulds interchangeable and reducing downtime. This standardization can lead to a more streamlined production line, enhancing overall productivity.

Selecting the Right Desma Shoe Mould

Choosing the correct desma shoe mould is crucial for any footwear production line. Factors to consider include the type of shoe being produced, the material of the mould, and the specific design requirements. Suppliers on Alibaba.com offer a wide range of desma shoe moulds to meet these varied needs, providing detailed information to assist buyers in making informed decisions without the pressure of promotional content.