Popular in your industry

Top categories

About coffee cup lid mould

Exploring Coffee Cup Lid Moulds

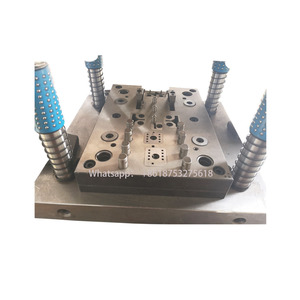

The realm of custom coffee cup lid production is intricate, involving precision engineering and design. A coffee cup lid mould is the cornerstone of creating functional and aesthetically pleasing lids that are essential for on-the-go beverage consumption. This category encompasses a variety of mould types, each tailored to produce lids that meet specific requirements and applications.

Types and Applications

There are multiple types of moulds available, each serving a distinct purpose in the lid creation process. From single-cavity moulds for bespoke designs to multi-cavity moulds for high-volume production, the selection is vast. These moulds cater to a range of applications, from disposable lids for everyday use to more durable options for reusable cups. The versatility of injection moulding for coffee cup lids allows for the production of lids that fit various cup sizes and styles, ensuring a secure seal and maintaining the beverage's temperature.

Material Considerations

Material selection is crucial when considering a coffee cup lid mould. Options include, but are not limited to, metals like iron for their durability and heat resistance. The choice of material affects the mould's longevity, the precision of the lid fit, and the overall quality of the final product. It's essential to select a material that aligns with the intended use and the desired lifespan of the mould.

Features and Advantages

A well-crafted coffee cup lid mould offers numerous features and advantages. For instance, standardizing certain elements such as lift bars, connection sizes, and clamp slots can streamline the manufacturing process. This standardization can lead to reduced production costs and increased ease of use across various moulds. Additionally, the ability to produce test samples ensures that the mould meets the exact specifications and requirements before full-scale production commences.

Customization and Precision

Customization is a key aspect of acquiring a coffee cup lid injection mould. The process begins with a detailed design phase, where specific needs are addressed, including the lid's functionality and compatibility with different cup designs. Precision is paramount in mould manufacturing, as the final product's quality is directly influenced by the mould's accuracy.

Choosing the Right Mould

Selecting the right coffee cup lid mould manufacturer is a critical decision that impacts the efficiency of production and the quality of the lids. It's important to engage with manufacturers who can provide expert advice, ensuring that the mould aligns with the production goals and material requirements. Alibaba.com serves as a gateway to connect with a diverse array of suppliers, each offering a wealth of information to aid in making an informed decision.