Introduction to Chain Grate Stokers

The chain grate stoker is a mechanized stoker system commonly used for managing the combustion process in industrial and large residential boilers. This system allows for the continuous addition of fuel at a controlled rate and is an integral part of the boiler's efficiency and operation.

Types and Applications

There are various types of chain grate stokers, each designed to cater to different boiler configurations and fuel types. The chain grate stoker boiler is particularly versatile, accommodating a range of fuels from coal to biomass. These stokers are pivotal in applications ranging from power generation to providing heat for industrial processes.

Operational Features

The chain grate stoker working principle involves the movement of a chain grate that transports the fuel across the combustion area. This allows for a uniform distribution of fuel and air, which is essential for consistent combustion and heat production. The design ensures that the boiler operates with enhanced fuel efficiency and reduced emissions.

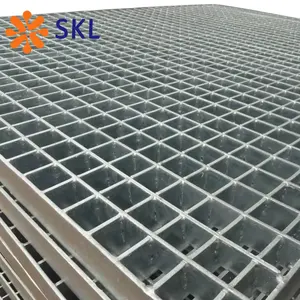

Materials and Construction

Constructed from durable materials capable of withstanding high temperatures and corrosive environments, grate stokers are built to last. The robust construction ensures that the system can endure the rigors of continuous operation, which is crucial for industrial applications.

Advantages of Chain Grate Stokers

Utilizing a chain grate system offers several advantages, including improved combustion efficiency, ease of operation, and maintenance. The automated nature of the chain grate stoker ensures a consistent flow of fuel, leading to optimal boiler performance and a reduction in labor costs.

Maintenance and Efficiency

Regular maintenance of the boiler chain grate stoker is essential to ensure efficient operation. The system's design allows for easy access to components for cleaning and repairs, minimizing downtime and maintaining the boiler's efficiency over its lifespan.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4