(107 products available)

Cassiterite is the primary metal of tin, and many products are sourced from it. Cassiterite ore concentrates are available in several options owing to the kind of machines that are used for the extraction and refining process.

Tin Slag

This is the remainder that is left behind after tin has been extracted. It comprises iron, titanium dioxide, and silicates, among other compounds. This tin slag is not entirely devoid of tin, and a small percentage of tin can still be calculated in the remaining material. Some industries make use of tin slag as a building material. The tin concentration of tin in slag is around 0.5 to 1.5%

Tin Ore

Stannolite is an ore mineral that contains tin. It is not like any other ore concentrates, as it is an entirely new mineral, thereby having properties of its own. The quantity of tin in this ore is quite high and can be anywhere between 3% to 32%

Bog Iron

This is a form of iron deposit that can be found in freshwater wetlands and lakes. When iron precipitates from water, it forms yellow or orange deposits that can sometimes hold traces of tin.

Ilmenite

This is an iron-titanium oxide mineral, which is also the main ore of titanium. This can also contain traces of tin and is located in different parts of the world. The concentration of tin can be very low - around 0.01 to 0.05% or may be higher, depending on the geological formation.

Depending on the use of ore concentrates, many industries and businesses look for ways to enhance the concentration of tin. There are several extraction and refining methods that can produce a high grade of cassiterite ore concentrate with world-wide demand.

Besides the types mentioned above, there are also diverse extraction methods for cassiterite concentrates:

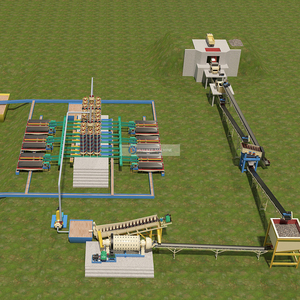

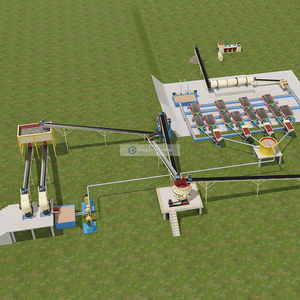

Gravity Separation

This is a widely used method for the concentration of cassiterite tin ore. The separation is based on the difference in specific gravity between cassiterite and gangue minerals or other interferences. The gravity separation methods include jigging, shaking tables, spiral chutes, and air deficiency tomato separators, among others.

Magnetic Separation

This method can be used to separate magnetic minerals from non-magnetic ones using a magnetic field. It can be utilized as a supplementary method to gravity separation or as a standalone method to concentrate cassiterite tin ore.

Flotation

This is a widely used method for concentrating minerals. It is based on the differences in the hydrophobic property of minerals. The method can be used to separate cassiterite from other gangue minerals.

The specifications of cassiterite ore concentrate vary depending on several factors, such as the mining location, the type of extraction method used, and the intended use of the concentrate.

The cassiterite ore itself does not need any routine maintenance; however, care should be taken when handling.

The major use of cassiterite is in the manufacture of tin, which is used to coat other metals to prevent corrosion. Tin also has several other uses. About half of the tin produced globally is used to make solder for electronic and electrical connections.

Geological Assessment

When considering investing in or purchasing cassiterite ore concentrate, the first step is understanding the geology of tin deposits. Geology will determine the distribution, grade, and quality of tin ore.

Supply Chain Analysis

Conduct an evaluation of the tin supply chain. This ranges from mining, processing, and refining until the final destination of the product. Determine possible risks, like political issues or logistical challenges that may disrupt the supply chain.

Quality of the Concentrate

Not all concentrates are the same. Some may contain impurities like tourmaline or muscovite. Choose a concentrate with high purity levels and minimal contaminants.

Geographical Sourcing

The origin of the ore can play a significant role in its market value. For instance, tin from certain countries may fetch a higher price due to its perceived quality or lower environmental concerns.

Production Methods

Understand how the ore was produced. Did the mine adhere to sustainable and responsible mining practices? Or were there environmental concerns related to its extraction?

Impurities in the Concentrate

Specific impurities in the concentrate can adversely affect the refining process. This could lead to increased production costs. Some impurities might even lower the tin's market value. Hence it is essential to choose a cassiterite ore concentrate free of impurities.

Reputation of the Supplier

Purchasing from a reliable supplier is fundamental. Ensure the supplier has a solid reputation and adheres to international standards in their products.

Tin Price Trends

The market for tin is ever fluctuating, dictated by demand dynamics from industries like electronics, automotive, and packaging. Remains informed about tin pricing trends to make educated purchasing decisions.

Q1: Is there demand for cassiterite ore concentrate?

A: Statistics show that around 350,000 tons of cassiterite ore concentrate were in demand globally in 2021. Demand is expected to increase due to the requirements for tin in many industries.

Q2: Which countries are the major suppliers of cassiterite ore concentrate?

A: The major suppliers of cassiterite ore concentrate include China, Brazil, Indonesia, Peru, Rwanda, and Burundi.

Q3: DoesHazard cassiterite ore concentrate?

A: According to studies conducted by the World Health Organization, cassiterite (TI02) is not deemed hazardous to health. When tin is inhaled at high doses, it can be harmful. Therefore, strain recipients should work under controlled conditions. Conversely, ore mining concentrates contain other minerals, such as asbestos, that can be fatal when inhaled. These mixtures require safety measures to avoid being hazardous.