Popular in your industry

Related Searches:

Top categories

About carbide insert m20

Introduction to Carbide Insert M20

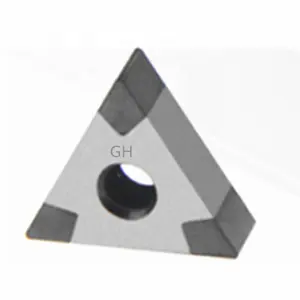

The carbide insert M20 is a pivotal component in the realm of machining, offering precision and durability for various turning operations. This category of tooling is designed to meet the demands of modern manufacturing, where efficiency and tool longevity are paramount. The M20 designation typically refers to the threading and size of the insert, which is crucial for compatibility with different turning tools.

Types and Applications

Carbide inserts such as the M20 come in diverse geometries and are engineered for specific applications. These include but are not limited to, threading, parting, and profiling tasks. The versatility of carbide turning inserts allows for their use in a multitude of industries, ranging from automotive to aerospace, where precision metal removal is required.

Features and Materials

Constructed from robust carbide materials, the M20 inserts are recognized for their ability to maintain hardness even at elevated temperatures. This intrinsic property is essential for high-speed cutting operations. The physical composition of carbide cutting tools ensures a balance of toughness and resistance to wear, which is critical for maintaining dimensional accuracy in repetitive machining tasks.

Advantages of Using Carbide Insert M20

Employing carbide lathe tools like the M20 insert can significantly enhance machining efficiency. Their capacity to withstand high temperatures without losing hardness translates into longer tool life and reduced downtime for tool changes. Moreover, the precision of carbide machining inserts ensures consistent quality in the production of symmetrical parts, a key factor in high-volume manufacturing.

Selection and Adjustability

The market offers a broad spectrum of carbide insert M20 shapes and sizes, each tailored for specific turning operations. The adjustability of these inserts is a noteworthy feature, allowing for swift modifications in machining parameters, which optimizes the turning process and enhances the adaptability of the tools to different tasks.

Conclusion

In conclusion, the carbide insert M20 stands as a fundamental tool in precision machining. Its material properties and design versatility make it suitable for a wide range of industrial applications. For professionals seeking to elevate their machining capabilities, the M20 carbide insert is an indispensable tool that promises efficiency and precision.