Popular in your industry

Top categories

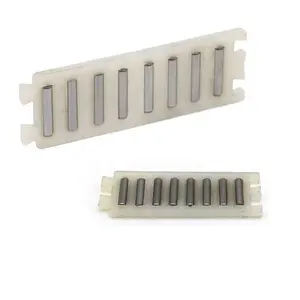

About bearing 620 z

Introduction to Deep Groove Ball Bearings

Deep groove ball bearings are among the most widely utilized types of bearings in the industry, with the bearing 620 z being a prominent example. These bearings are designed to support radial loads and a certain degree of axial load in both directions. Their versatility and efficiency make them suitable for a wide range of applications.

Types and Configurations

The bearing 620 z category encompasses various types, including the standard single-row configurations and the 620 zz bearing, which features double metal shields for enhanced protection against contaminants. These bearings come in both miniature and large sizes, catering to different industrial requirements.

Materials and Design Features

Materials play a crucial role in the functionality of bearings. The bearing 620 z is typically crafted from high-grade chrome steel, ensuring durability and resistance to wear and tear. Stainless steel variants are also available, offering corrosion resistance for harsh environments. The deep groove design allows for high speeds and supports both radial and axial loads efficiently.

Applications Across Industries

Versatility is a hallmark of the 620 zz bearing, making it suitable for a multitude of applications. These bearings are found in electric motors, automotive components, home appliances, and industrial machinery. Their design ensures they are a reliable component in both high-speed and high-precision scenarios.

Advantages of Deep Groove Ball Bearings

The bearing 620 z offers several advantages, including low friction, high load capacity, and minimal maintenance requirements. Their simple design contributes to ease of use and replacement, making them a cost-effective solution for various mechanical assemblies.

Choosing the Right Bearing

Selecting the correct bearing 620 z is crucial for ensuring optimal performance. Factors to consider include the operational environment, load requirements, and desired lifespan. With a comprehensive selection available, finding the appropriate bearing for specific industrial needs is streamlined.