(104 products available)

The automobile sensor signal simulation tool MST 9000 is a versatile handheld device that is used to diagnose and troubleshoot a wide range of automotive issues. The tools come in different types, which are:

1. Voltage Signal Simulation

Voltage signal simulation is used to simulate and generate voltage signals that are typically produced by various sensors in an automobile. These signals are then sent to the vehicle's control modules, tricking them into believing that the normal sensor data is being provided. This allows technicians to isolate and test specific components of the sensor system without needing the actual sensor to be present or functional.

2. Current Signal Simulation

Current signal simulation, on the other hand, focuses on mimicking the current-based signals that certain sensors provide to the control modules. These sensors often measure parameters like pressure, temperature, or position, where changes need to be detected as variations in current. By generating equivalent current signals, the automobile sensor signal simulation tool can help diagnose issues in complex sensor systems that rely on precise measurement of physical variables.

3. Frequency Signal Simulation

Some sensors in modern vehicles, such as wheel speed sensors or knock sensors, utilize varying frequencies to convey information. Frequency signal simulation involves creating signals with specific frequencies, along with their amplitudes and waveforms, to replicate the behavior of these sensors. This is particularly useful for diagnosing problems in dynamic systems where parameters need to be monitored and adjusted in real time.

4. Multi-Channel Simulation

Advanced automobile sensor signal simulation tools often feature multi-channel capabilities. This enables them to generate and monitor multiple sensor signals simultaneously. Multi-channel simulation is indispensable for diagnosing intricate issues involving several interconnected sensors and control modules. It provides a comprehensive view of the entire sensor network's health and performance, facilitating pinpointing problems that may arise from interactions between different components.

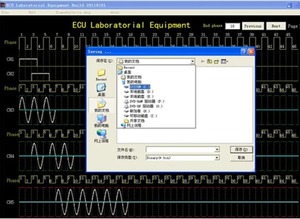

5. Graphical User Interface (GUI)

Many modern sensor signal simulation tools are equipped with a graphical user interface. This makes it easier for technicians to visualize the simulated signals, monitor real-time data, and interact with the tool intuitively. A GUI enhances usability and allows for more efficient data analysis and manipulation, streamlining the diagnostic process.

1. Regular Inspection:

Users should regularly check the automobile sensor signal simulation tool for any wear and tear. They should inspect the cables, connectors, and sensors for any physical damage or corrosion that may affect their performance. Regular inspections can help identify potential issues early on and allow for timely repairs or replacements.

2. Cleanliness:

Maintaining cleanliness is essential for the automobile sensor signal simulation tool. Users should keep the device and its components clean from dust, dirt, and debris. Accumulated contaminants can interfere with sensor readings and signal accuracy. A gentle wipe with a soft cloth or the use of appropriate cleaning agents can help maintain the tool's cleanliness.

3. Proper Storage:

Users should store the automobile sensor signal simulation tool in a suitable environment when not in use. It should be kept away from extreme temperatures, humidity, and direct sunlight. Additionally, it should be stored in a dry and dust-free area to prevent damage to its sensitive components. Proper storage can extend the lifespan of the tool and ensure its reliability when needed.

4. Follow Manufacturer's Instructions:

Users should always adhere to the maintenance guidelines and instructions provided by the manufacturer of the automobile sensor signal simulation tool. Each tool may have specific requirements for maintenance, such as recommended cleaning agents, lubrication intervals, or calibration procedures. Following the manufacturer's instructions ensures that the tool operates optimally and maintains its accuracy over time.

When buying an automobile sensor signal simulation tool, consider the following:

Understand the Needs:

Before heading to the market to buy a simulation tool, understand the needs first. What is the primary purpose of the tool? Which sensors need testing and diagnostics? Knowing this will help select a tool that meets the needs.

Budget:

There are many options for MST 9000 tools in the market. Therefore, set a budget to avoid overspending. However, don't go for the cheapest tool because it might lack important features.

Features:

When buying the MST 9000, consider the features it comes with. A good simulation tool should have the following features:

1. User Interface: The tool should have a simple and easy user interface. It should also have a good display screen to show the results.

2. Portability: Choose a simulation tool that is lightweight and can be easily carried.

3. Compatibility: Ensure that the tool is compatible with various sensors. It should also be compatible with the vehicle's make and model.

4. Battery life: Choose a tool with long battery life or one that can be charged quickly. This will ensure the tool runs for a long time without shutting down.

Brand:

Consider the brand of the simulation tool. Go for reputable brands known to manufacture quality and long-lasting products. Also, choose a brand that offers after-sales services like warranty and maintenance.

Reviews:

Consider what other people say about the simulation tool. Read online reviews to know the advantages and disadvantages of the tool.

Test:

If possible, test the simulation tool before buying it. This will ensure that the tool meets all the needs and requirements.

Only trained technicians should use the automobile sensor signal simulation tool mst 9000. If users do a DIY check, they should ensure only certified auto mechanics use it to avoid damaging the vehicle.

To replace the tool mst 9000, users must do a follow-up on the maintenance act they did previously. The mst 9000 is a multi-functional tool that services and repairs many functions. But to avoid any damage, users should not attempt to use it on the first try.

Meanwhile, here are the steps to get the mst 9000 service.

It is important to note that vehicle maintenance using high-tech tools like the mst 9000 costs a lot. So, before any maintenance act, users should think twice.

Q1: What is an automobile sensor signal simulation tool MST 9000?

A1: The automobile sensor signal simulation tool, MST 9000, is a diagnostic device used to simulate and generate signals for various sensors in a vehicle. This tool allows technicians to test and evaluate the performance of sensors and their corresponding control modules, ensuring proper functionality and reliability.

Q2: Why is the MST 9000 sensor signal simulation tool important for vehicle maintenance?

A2: The MST 9000 sensor signal simulation tool is important for vehicle maintenance because it enables precise testing and diagnostics of critical sensors. By simulating sensor signals, technicians can identify faulty sensors, wiring issues, or problems with control modules. This helps in quickly locating the root cause of sensor-related problems, reducing guesswork, and saving time and costs. Ultimately, the MST 9000 ensures that sensors function correctly, maintaining optimal vehicle performance, emissions control, and safety systems.

Q3: What sensors can be tested with the MST 9000 sensor signal simulation tool?

A3: The MST 9000 sensor signal simulation tool is capable of testing a wide range of sensors in a vehicle. This includes but is not limited to: temperature sensors, pressure sensors, position sensors, oxygen sensors, mass air flow sensors, crankshaft and camshaft position sensors, speed sensors, throttle position sensors, and many others.

Q4: How does the MST 9000 help in diagnosing sensor-related issues?

A4: The MST 9000 helps in diagnosing sensor-related issues by allowing technicians to simulate sensor signals and interact with the vehicle's control systems. By generating specific signals, they can test the response of control modules and identify potential faults. This enables precise diagnostics of sensor-related problems, pinpointing defective sensors, wiring issues, or control module malfunctions.

Q5: Is the MST 9000 a user-friendly tool for automotive technicians?

A5: Yes, the MST 9000 is designed to be a user-friendly tool for automotive technicians. It typically features an ergonomic design, a clear display for easy reading, and a straightforward interface for intuitive operation. Additionally, the MST 9000 is often equipped with various functions, including sensor signal simulation, analysis, and diagnostic capabilities, making it a versatile tool for sensor testing and module diagnostics.