Popular in your industry

Top categories

About automatic hot glue dispensing machine

Introduction to Automatic Hot Glue Dispensing Machines

Automatic hot glue dispensing machines are essential tools in various industrial applications, designed to deliver precise adhesive application. These machines are engineered to streamline production processes, ensuring consistent glue dispensing for a multitude of tasks.

Types and Configurations

There are several types of glue dispensing systems, each tailored to specific industry needs. From tabletop units for small-scale operations to large, floor-standing models for high-volume production, the configurations are as varied as the applications they serve. Understanding the specific type that aligns with your operational needs is crucial for optimal performance.

Applications and Uses

The versatility of hot melt adhesive systems allows for their use across numerous sectors. They are widely utilized in packaging, electronics manufacturing, automotive assembly, and more. The precision of these machines ensures they are indispensable for tasks requiring consistent application of adhesive with minimal waste.

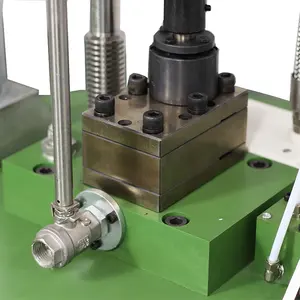

Features and Functionality

Key features of industrial glue dispensers include programmable dispensing patterns, adjustable flow rates, and temperature control. These features contribute to their ability to handle various adhesive viscosities and compositions, making them suitable for a range of materials and applications.

Materials and Advantages

Constructed from durable materials, automatic dispensing machines are built to withstand the rigors of industrial environments. The advantages of using these machines include improved production speed, reduced material waste, and enhanced product quality through the delivery of uniform adhesive application.

Choosing the Right Machine

Selecting the appropriate hot glue machine involves considering factors such as the type of adhesive, the volume of adhesive needed, and the specific application requirements. It's important to review the specifications of each machine to ensure it meets the demands of your production line.