Types of A-axis CNCs

The A-axis CNC refers to an imaginary axis that allows rotating objects horizontally. Typically, the A-axis works in tandem with a three- or four-axis CNC machine to create high-quality parts and products. Some of the most popular types of A-axis CNC machines include the following:

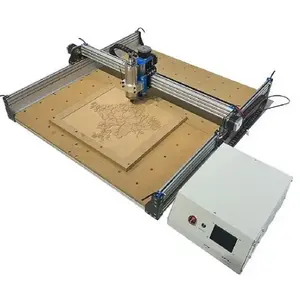

- A-axis CNC router: An A-axis CNC router is great for carving, milling, and cutting different materials. This tool features a rotating spindle with a fixed CNC machine frame. In most cases, the CNC machine has three additional linear XYZ axes. This machine works well for artistic projects, sign making, and product prototyping.

- A-axis CNC mill: This type of machinery can perform all the regular milling operations, plus it can rotate the workpiece and the tool being used to achieve a greater variety of cuts. Often, A-axis CNC mills are more complex than A-axis CNC routers. They may have a combination of laser cutting and razor-blade technology to achieve their desired results.

- A-axis CNC plasma cutter: A plasma cutter uses ionized gas (plasma) to cut through metal objects and workpieces. This type of A-axis CNC machine offers increased speed, precision, and control when cutting complex metal patterns. The device is mainly used in manufacturing, automotive repair, or metal fabrication industries.

- A-axis laser engraver: This device works by using a laser beam to engrave or mark on different materials. The A-axis engraver is a precise tool that allows rotating objects horizontally. Combining this function with the previous three linear axes creates a highly accurate and automated engraving process. The laser engraver is suitable for working on wood, acrylic, metal, glass, and other materials.

Specification and Maintenance of A Axis CNC

The following table summarizes the specifications of a typical A-axis CNC router machine.

- Machine Size: A 3.5m*6m CNC axis machine size indicates that the maximum workpiece that it can handle is up to 3.5 meters in height and up to 6 meters in length.

- Motor: The motor for the A-axis is typically a stepper motor with a 3 Nm holding torque. Such a torque is sufficient for routing machines to process various materials, such as wood, acrylic, and PVC.

- Rotational Speed: The rotational speed of an A-axis CNC machine indicates how fast the A-axis can rotate. An A-axis CNC router axis A speed of 3500 means it can make 3,500 rotations per minute. This speed is enough for most CNC machining jobs and works precisely on materials.

- Control Software: The type of software that controls the machine.

Regular maintenance of an A-axis CNC machine can help extend its life and keep it in good working condition. The following tips can help maintain the machine effectively.

- Clean the rail and drag chain. Do this after removing the debris in the guiding rail and drag chain. Use an air gun to blow out any residual dirt or dust in the chain and rail. Then, use a clean cloth to wipe both parts.

- Lubricate the guide rail and drag chain. Apply lubricant oil on the wiping cloth and use it to wipe the guiding rail. The drajl chain, on the other hand, has lubricant grease that it should apply to its moving parts.

- Regularly inspect the spindle motor. Users should check the spindle motor for signs of damage, such as unusual sounds and overheating. If there are signs of damage, please repair them quickly.

- Clean and lubricate the tool holder. Wipe the tool holder clean after removing the tool. Lubricate any movable parts of the tool holder before using it again.

- Check the air compressor. Make sure that the air compressor provides adequate pressure to the machine. The usual requirement is about 6 kg/m2 or higher.

- Ensure proper spindle tightening. When fixing a router bit, ensure that the spindle tightens it properly to avoid vibration during the routing process, which can affect the machining quality.

- Keep the machine covered when not in use. A CNC machine is vulnerable to dust and dirt when it is not in use. Therefore, keeping the machine covered when it is not being used will help protect it.

Scenarios of 1-axis CNCs

1-axis CNC machines are used for a variety of tasks in different industries. Their simple design is perfect for using low-cost or uncomplicated models. Here are some common uses of 1-axis CNCs:

- 1-axis CNCs are used to manufacture parts by cutting, drilling, and engraving on different materials.

- 1-axis CNCs used for material handling can load components from a storage system to a manufacturing process or vice versa.

- CNC plotters are 1-axis CNC machines. They use 1-axis for the movement of a pen to draw images, diagrams, and designs on different materials.

- 1-axis engravers are used to make engravings, markings, and labels on various solid objects and materials.

- 1-axis CNCs are used in a manufacturing line for assembling basic components and parts. They are integrated into robotics systems for picking objects and transferring them from one place to another for matrix operations.

- 1-axis CNCs are widely used in woodworking for applications like engraving and cutting wood, plastics, and other similar materials.

- In sign-making and advertisement industries, 1-axis CNC machines are used for cutting and engraving signs, letters, and logos on various materials such as acrylic, wood, and aluminum.

- 1-axis CNC machines are often used to process the edges of solid surfaces by beveling, rounding, or chamfering.

- These machines perform engraving work, adding personal touches like monograms, designs, and patterns to objects made of metal, wood, and plastic materials.

- 1-axis CNC cutting machines are primarily used for fabric transfer and precision to improve production efficiency.

How to Choose A Axis CNC

When picking an A axis CNC machine, several factors need to be considered to ensure the best fit for the intended use. First among them is the material of choice, which can range from wood composites to plastics. The machine's ability to handle these diverse materials without compromising quality is paramount. Additionally, it's crucial to select a device that can accommodate both budget constraints and floor space.

One must also match the machine's maximum A axis CNC workpiece size with the dimensions of the objects usually handled. Furthermore, the choice of bits and the A axis CNC spindle speed plays a pivotal role in achieving varied finishes and engraving depths. Another consideration is the software compatibility; the CNC machine's program should seamlessly interface with design software for a smooth workflow.

Importantly, consider whether a 3D A axis CNC machine or a more basic model like a wood CNC machine suits one's needs better. While the latter may be sufficient for simpler tasks, the former offers advanced capabilities like axial rotation, which can enhance productivity and project complexity. It is also crucial to assess the A axis CNC machine's carving precision and speed, as these attributes directly impact the final product's quality and production efficiency. As a last point, given the potential risks, it's essential to prioritize A axis CNC machines with robust safety features, such as emergency shutdowns and protective enclosures.

A Axis CNC Q&A

Q1: How does the accuracy of a 4th axis CNC A rotatory compare to that of a standard 3 axis CNC machine?

A1: When the workpiece has symmetrical geometry, both machines will have comparable accuracy. However, concerning offsets, the 3 axis CNC will have a better accuracy of about 0.025 mm, while the A axis CNC can achieve an accuracy of 0.05 mm.

Q2: Can the A axis on the CNC machine be upgraded or replaced with a different size?

A2: Yes, it is possible to upgrade or replace the A axis. However, before doing so, one must consult the machine’s manufacturer to see any compatibility requirements.

Q3: Does the A axis require special maintenance procedures?

A3: No, there is no special maintenance requirement for the A axis. However, users should periodically inspect the rotary for any signs of damage. They should also lubricate the moving components to ensure maximum performance and smooth operation.

Q4: Can an A axis CNC rotary table work with different types of materials, such as metal, wood, or plastic?

A4: Yes, an A CNC axis can work with different materials, including plastics, metals, and wood. However, the material compatibility will depend on the specifications of the particular A axis model.

Q5: Can two 4th axis CNC A rotaries be attached to one CNC machine?

A5: While technically possible, it is not recommended to install two A 4th axis at once. Doing so might interfere with the CNC machine's control system and overall performance. Additionally, the workpiece setup would be complex and challenging.

Ready to Ship

Ready to Ship