(39172 products available)

A 6-inch pipe is a type of pipe with a diameter of 6 inches, commonly used in various industries for transporting fluids, gases, and materials. These pipes come in different types, such as:

Steel Pipe:

Steel pipes are commonly used for transporting water, gas, and sewage. They are also used in construction for structural support. The application determines the type of steel pipe used. There are two main types of steel pipes: seamless and welded pipes. Seamless steel pipes are made without a joint or weld. They are manufactured through the extrusion process, creating a solid steel pipe that can be heated and pushed through a mold that has the desired diameter. The pipe is then cooled and hardened. Seamless pipes are known for their high strength and ability to withstand pressure. They are usually used in applications where pressure is a big deal, like oil and gas transportation. Seamless steel pipes come in different grades, like ASTM A106 and ASTM A53. Welded steel pipes, on the other hand, are made from rolling steel sheets into a cylindrical shape and welding the seam. They are less expensive to produce and can be made in larger diameters. Welded pipes are used in applications that don't require high pressure, like water supply lines. They are classified into ERW (Electric Resistance Welded) and LSAW (Longitudinal Submerged Arc Welded) based on the manufacturing process.

Galvanized Steel Pipe:

These pipes are steel construction, but they have a layer of zinc on the outside. This zinc coating protects the pipes from rust and corrosion. This makes galvanized steel pipes a popular choice for outdoor projects. There are two main types of galvanized steel pipes: welded and black steel pipes. While both welded and galvanized pipes have similar applications, welded pipes are more prone to corrosion since they don't have a galvanized coating. However, both are great for carrying water, gas, and sewage.

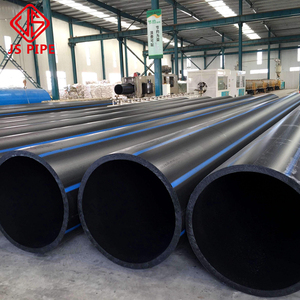

HDPE Pipe:

High-Density Polyethylene (HDPE) pipes are plastic pipes with very high-density polyethylene material. They are lightweight, flexible, and resistant to corrosion. HDPE pipes are used in a variety of applications, such as water supply, gas transmission, sewage disposal, industrial wastewater, electrical and communication ducting, and landfill drainage systems. These pipes have a smooth inner surface, which allows fluids to flow freely. They are also easy to install because of their lightweight nature and flexibility. HDPE pipes are also recyclable, which makes them an environmentally-friendly option.

PVC Pipe:

PVC (Polyvinyl Chloride) pipes are also plastic pipes. They are lighter than HDPE pipes and are used in applications like drainage, waste disposal, and vent piping. PVC pipes are very resistant to corrosion and chemicals. They are also watertight, meaning they prevent water from leaking out. This makes them a popular choice for sewer and drain lines. PVC pipes come in different sizes and classes, making them versatile for many applications.

Water Supply:

6-inch metal pipes are used for central water supply systems. They carry a lot of water to homes, buildings, and other places. Their size is good for meeting the water needs of different users.

Sewer Lines:

These pipes are also used as sewer lines. They are strong and resistant to rust, which is important for carrying waste water safely.

Irrigation:

Farmers use 6-inch PVC pipe for irrigation systems. They help distribute water to crops and ensure agriculture is done properly.

Draining:

These pipes support draining water from rain, floods, and other sources. They help prevent water from accumulating and causing damage in areas where it is not needed.

Gas Lines:

6-inch pipes carry gas safely through underground systems. They have tight-fitting joints that prevent leaks. Gas companies rely on these pipes to deliver gas to homes and businesses.

Diameter:

The diameter of these pipes is 6 inches, which is about 15.24 centimeters. This makes them good for carrying a lot of water or other fluids. Their diameter means the size of the hole in the pipe.

Materials:

These pipes are made of different materials like metal, PVC, or concrete. Each material has its advantages depending on the use. For example, PVC pipes are lighter and easier to work with, while metal pipes are stronger.

Length:

These pipes come in different lengths. Longer pipes mean fewer joints are needed, which can help water flow better. Shorter pipes are easier to transport and install.

Pressure Rating:

These pipes can resist pressures from 100 to 200 PSI or more. Higher pressure ratings are used in applications where a lot of pressure is expected, while lower ratings are used in less demanding situations.

Corrosion Resistance:

Many 6-inch pipes are treated to resist rust and corrosion. This is important because they are often exposed to water, moisture, and other harsh conditions.

Ease of Installation:

These pipes are designed to be easy to install. They have features like slip joints or compression fittings that make connecting them simpler.

There are different applications of a 6-inch pipe across various industries. These include:

Construction

Construction sites use 6-inch pipes for structural support and other applications. For instance, in foundation construction, these pipes are used to create deep piers or piles. They are filled with concrete to transfer loads to the stable soil or bedrock. Also, these pipes are used as formwork for cast-in-place concrete. The 6-inch metal or plastic pipe is filled with concrete to create columns, beams, and walls. Additionally, 6-inch pipes are used as temporary props or shoring. They support walls, floors, and other structures under construction until the permanent supports are installed.

Water Supply

A 6-inch pipe is widely used in public and private water supply systems. It is used to transport clean, potable water to residential, commercial, and industrial buildings. A 6-inch pipe can also be used in irrigation systems. A 6-inch metal or plastic pipe is preferred due to its high volume and low friction loss. It can also be used in municipal water distribution networks. It helps reduce the pressure in water distribution systems, making it safer and easier to handle.

Oil and Gas

These pipes transport oil, natural gas, and other hydrocarbons from one point to another. A 6-inch pipe is used to transport crude oil, natural gas, and other products from wells to refineries or processing plants. It is also used to transport refined products such as gasoline, diesel, and jet fuel to storage facilities and distribution terminals. Additionally, these pipes are used in offshore oil and gas extraction. They are essential in transporting materials such as water, oil, gas, and slurries in deep-water drilling sites.

Agriculture and Irrigation

These pipes are also used in agriculture, particularly in irrigation. They are used to transport water from rivers, lakes, or reservoirs to farmlands. Water transported through these pipes is used for crop irrigation, livestock consumption, and other agricultural activities. Additionally, these pipes reduce water evaporation and seepage losses, making them more efficient than open ditches or canals.

Industrial Applications

The 6-inch pipe is prevalent in many industries. For example, in manufacturing industries, these pipes transport liquids such as chemicals, water, milk, and juices. In the food and beverage industry, these pipes are used to transport liquid and semi-liquid materials such as water, oils, and syrups. 6-inch pipes are also used in chemical industries to transport different chemicals during manufacturing processes.

When choosing the right pipe, consider various factors that will affect its application and performance. Here are some of them:

Material:

The material of a pipe affects its weight, durability, and cost. PVC pipes are lightweight and affordable, but they can't handle high temperatures and pressures. Copper pipes are long-lasting and resistant to corrosion, but they're more expensive. Steel pipes, especially those galvanized or rust-resistant, are very durable and suitable for high-pressure applications. When choosing a material, consider the budget, pressure requirements, and environmental factors.

Schedule:

The schedule number indicates the pipe's wall thickness, with a higher number signifying a thicker wall. A thicker wall increases the pipe's strength and ability to carry fluids under pressure. For applications with high pressure or rough handling, a higher schedule pipe is ideal. Lower schedule pipes are sufficient for lower pressure applications and are more cost-effective.

Joint type:

The type of joint affects installation and the pipe's performance. Welded joints create a permanent, strong bond between pipes, ideal for high-pressure applications. Threaded joints are easy to assemble and disassemble, suitable for applications requiring frequent maintenance. Slip joints are also easy to use but less strong than threaded and welded joints.

Length and diameter:

The length and diameter of a pipe affect its fluid carrying capacity. A longer pipe segment carries more fluid, while a wider diameter increases the flow rate. It's important to balance the application requirements and the available space, as larger diameter and longer pipes require more physical space.

Compatibility:

Ensure the pipes are compatible with the fluids carried. For example, PVC works well with most water-based fluids, while copper is suitable for potable water. Consider the fluid's temperature, acidity, and pressure when choosing a pipe material to prevent corrosion or degradation.

Q: How is a 6-inch pipe welded?

A: The pipe can be welded using a TIG or MIG welding technique. The choice depends on the application and the user's preferences. MIG is usually faster and easier, while TIG offers a more robust and cleaner weld.

Q: How is a 6-inch pipe threaded?

A: A pipe threading machine is used to create external threads on the workpiece's ends. The machine offers high precision and a better finish. It is also possible to thread the pipe using a die, but this requires more effort and time.

Q: How to calculate the flow rate of a 6-inch pipe?

A: The flow rate can be calculated using the formula Q = V x A, where Q is the flow rate, V is the velocity of the fluid, and A is the cross-sectional area of the pipe. It is important to note that the flow rate will vary depending on the type of fluid and the pressure.

Q: How to increase the pressure in a 6-inch pipe?

A: One way to increase the pressure is by reducing the diameter of the pipe at certain points. This is known as the Venturi effect. However, this technique should be carefully analyzed and implemented by professionals.