(22261 products available)

A 2 post lift is an essential piece of equipment in vehicle maintenance and repair workshops. It is designed to hoist vehicles to a height where they can be accessed easily. The 2-post lift is suitable for a wide range of vehicles from small cars to larger trucks. There are several types of two-post lifts each designed to meet specific needs in workshops.

Symmetrical 2-post lifts

As the name suggests, symmetrical two-post lifts have two lifting arms that are the same length and positioned in a parallel arrangement. The arms lift vehicles from their designated lifting points, which are located at the vehicle's frame edges. Symmetrical two-post lifts are ideal for lifting vehicles that have a balanced weight distribution. They provide even access to both sides of the vehicle. The symmetrical two-post lifts are commonly used in service stations and workshops that deal with vehicle repairs and maintenance.

Asymmetrical 2-post lifts

The asymmetrical two-post lifts are designed with two lifting arms that have different lengths. The two arms are positioned at an angle to each other. One arm is longer and allows for more extension under the vehicle. The asymmetrical lifts are ideal for lifting vehicles that have an unbalanced weight distribution. They provide more access to the vehicle's interior. The asymmetrical two-post lifts are the most suitable lifts for sports cars.

Reversible 2 post lifts

The reversible two-post lifts come with arms that can be adjusted to be either symmetrical or asymmetrical. The user can change the lift configuration based on the specific vehicle being lifted. The reversible lifts offer more flexibility and adaptability in workshops that deal with different vehicle models. The reversible two-post lifts are also commonly found in mobile service units.

Heavy-duty 2 post lifts

The heavy-duty two-post lifts are designed to handle large and heavy vehicles such as trucks and commercial delivery vehicles. The lifts are equipped with powerful hydraulic systems and robust construction to ensure safety and stability when lifting heavy loads. The heavy-duty two-post lifts are extensively used in commercial vehicle service centers and maintenance workshops.

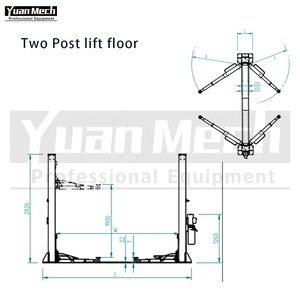

Clear floor two-post lifts

The clear floor two-post lifts are designed with the lifting mechanism mounted on the floor. The lifts do not have any obstructions between the two posts. The clear floor lifts provide unobstructed access to the vehicle's underbody and are suitable for low-ceiling workshops. The clear floor two-post lifts are commonly used in vehicle service stations and maintenance workshops.

Floor-plate 2 post lifts

The floor-plate two-post lifts have a unique design where the lifting mechanism and hydraulic system are mounted on the floor. The lifts are suitable for workshops with limited space and low ceilings. The floor-plate two-post lifts are ideal for small vehicle lifts.

Capacity

Every 2-post car lift has a lifting capacity that indicates how much weight it can safely handle. It typically ranges from 7,000 to 20,000 pounds. For example, a 2-post lift with a capacity of 10,000 pounds can raise vehicles weighing up to 10,000 pounds.

Height

Each 2-post lift has a maximum lifting height, which is the highest point a vehicle can be raised during the lifting process. The height of a two-post lift is usually between 72 and 100 inches. For example, if a lift has a maximum height of 80 inches, it can lift vehicles up to 80 inches tall.

Width and footprint

The width and footprint of a 2-post lift determine how much space it will take up in the garage. Two-post lifts range in width from 100 to 150 inches, and the footprint is usually around 200 by 250 inches. For example, a lift with a width of 120 inches and a footprint of 220 by 250 inches will occupy a larger area than a lift with a width of 100 inches and a smaller footprint.

Voltage and power consumption

Each 2 post lift is powered by electricity, and its voltage and power consumption are important specifications. The voltage of a two-post lift is usually 110 or 220 volts, and the power consumption ranges from 1 to 5 horsepower. For example, a lift with 220 volts and 3 horsepower can generate more lifting power than a lift with 110 volts and 2 horsepower.

Lifting mechanism

Every 2-post lift has a lifting mechanism that determines how the vehicle is raised. The most common lifting mechanism for a two-post lift is hydraulic or screw. For example, a hydraulic lift uses hydraulic fluid to raise and lower the vehicle, while a screw lift uses screws to lift the vehicle.

2-post lifts need regular maintenance to ensure that they are safe and effective. The following are some tips on how to maintain a 2-post lift:

Choosing a 2-post lift can be challenging because there are several things to consider, such as the lifting capacity, installation requirements, safety features, and so on. Here are the factors that will help choose a 2-post lift:

The first thing to consider when purchasing a 2-post lift is the lifting capacity. Buyers should ask themselves the vehicles they will be lifting using the 2-post lift. If it’s light-duty vehicles, a 2-pist lift with a capacity of 10,000 lbs will be enough. For heavier vehicles like trucks or larger SUVs, consider getting a 2-post lift with a capacity of 14,000 lbs or more.

Consider the installation requirements of a 2-post lift before purchasing one. Make sure the area where the lift will be installed has a ceiling height of at least 12 ft or more. This is to ensure there is enough space for vehicle lifting and overhead clearance. Additionally, the floor where the 2-post lift will be installed should be level and strong enough to support the lift and the vehicles' weight.

Another factor to consider is the safety features of the 2-post lift. Business owners should choose a 2-post lift with superior safety features like Locking systems, safety codes, and overhead clearance. The security features help minimize accidents and ensure safe vehicle lifting and maintenance.

Consider the adjustable width of the two-post lifts. Buyers who deal with various vehicles should purchase a two-post lift with adjustable lifting arms and a wide span. This is to accommodate different vehicle sizes and ensure a secure and stable lift.

Choose a 2-post lift with superior construction material and quality. Most lifts are constructed with high-quality steel for durability. A two-post lift with superior construction lifts has a longer lifespan and requires less maintenance.

Business owners should consider the power requirements of the two-post lifts before purchasing one. Most 2-post lifts use standard 110V or 220V electrical power. Ensure the area where the lift will be installed has the right electrical power to operate the lift safely and efficiently.

Lastly, buyers should consider the budget. 2-post lifts come in different prices depending on the size, capacity, and features. Set a budget and choose a lift that meets the budget without compromising the quality.

Replacing a two-post car lift is a complex task, but with the right tools, knowledge, and safety precautions, it can be achieved successfully. Here are the steps to take:

Power Disconnection

Before starting any replacement work, ensure that the power supply to the two-post lift is disconnected. This can be achieved by unplugging it from the wall outlet or by turning off the circuit breaker. This step is crucial for preventing any electrical accidents.

Assemble Necessary Tools

Make sure to have all the necessary tools required for the replacement. This may include wrenches, sockets, screwdrivers, pliers, a lift for heavy components, and others. It is also advisable to have some electrical testing tools to ensure that the power supply is disconnected.

Read the Manual

Before doing anything, ensure to read and understand the manufacturer's manual. The manual includes important information regarding disassembly and assembly, including safety precautions and specific instructions for the particular model of the lift.

Check Warranty and Service Agreement

If the two-post lift was installed by a professional service, it is advisable to contact them before attempting any replacement. This is to ensure that the warranty is still valid and to get more informed assistance regarding the replacement process.

Prepare the Work Area

Ensure that the work area is clean and free of any obstructions. This includes removing any tools, equipment, or other items that may hinder the replacement process. A clean work area will reduce the risk of accidents and make the replacement process smoother.

Safety Precautions

Always use appropriate personal protective equipment (PPE) during the replacement process. This may include safety glasses, gloves, steel-toed boots, and hearing protection. Follow all safety precautions outlined in the manual and use the lift only for its intended purposes.

Disconnect Hydraulic and Electrical Connections

Once it is certain that the power supply is disconnected, start disconnecting the hydraulic and electrical connections. It is important to carefully follow the instructions in the manual to avoid damaging any components. Take pictures or make notes of the connections to ensure proper reassembly.

Disassemble the Lift

Once the electrical and hydraulic connections are disconnected, start disassembling the lift. Follow the instructions in the manual to safely disassemble each component. Use the appropriate tools and take care not to damage any parts during disassembly.

Install the New Lift

Once the old lift is completely disassembled, start installing the new lift. Follow the instructions in the manual for assembly and installation. Ensure that all components are tightened and properly aligned.

Reconnect Electrical and Hydraulic Connections

Once the new lift is installed, reconnect the electrical and hydraulic connections following the instructions in the manual. Ensure that all connections are secure and leak-free.

Test the Lift

Before using the lift for vehicle lifting, perform a test to ensure that it functions properly. Follow the testing procedures outlined in the manual and verify that all safety features work adequately.

Final Inspection

Perform a final inspection to ensure that all components are installed correctly and that the lift operates safely. Check for any unusual noises, leaks, or other issues before using the lift.

Q: Can an extension be added to a 2-post lift?

A: No, extensions should not be added to 2-post lifts. Doing so can compromise safety and affect the lift's performance.

Q: How often should a 2-post lift be inspected?

A: A 2-post lift should be inspected at least once a month. However, it is advisable to check it before each use to ensure safety.

Q: Can a 2-post lift handle heavier vehicles?

A: A 2-post lift can handle heavy trucks and commercial vehicles. Always check the lift's specifications and the vehicle's weight before lifting.