(138241 products available)

100 rail is a standardized model train track system that is widely used by hobbyists and model train enthusiasts. It is also known as ""narrow gauge"" because its rail profile is 2.5 centimeters wider than the standard gauge. This allows for more realistic operation of model trains. There are several types of 100 rail tracks, each with its distinctive features and advantages.

Code 100 rail:

Code 100 rail is the most common type of 100 rail track. It has a rail height of 100 thousandths of an inch, which is approximately 2.54 centimeters. This makes it suitable for a wide range of model trains, from steam locomotives to modern electric trains. Code 100 rails are compatible with most model train wheels, making them a popular choice for hobbyists.

Code 83 rail:

Code 83 rail is another type of 100 rail track. It has a rail height of 83 thousandths of an inch, or about 2.11 centimeters. This makes Code 83 rails more realistic for models of narrow-gauge trains, as the rail profile is closer to the actual dimensions. However, Code 83 rails are not compatible with all model train wheels, so hobbyists need to check the compatibility before using this type of track.

Code 75 rail:

Code 75 rail is the least commonly used type of 100 rail track. It has a rail height of 75 thousandths of an inch, or about 1.91 centimeters. This makes Code 75 rails suitable for models of older narrow-gauge trains, as the rail profile is similar to the tracks used by many historical locomotives. However, Code 75 rails may cause some issues with modern model train wheels, as the track gauge may be slightly different.

In addition to these three types of 100 rails, there are also variations in track construction and design, such as the use of different materials for rails and ties.

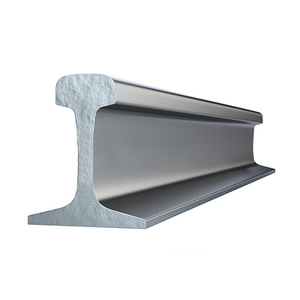

Here are some general specifications for the 100 rail that buyers should know:

Material:

The 100 rail is made from steel or other alloys that are durable and can resist corrosion and wear. The type of steel used in 100 rails is different, and it has a high tensile strength. This means that it can withstand a lot of pulling force without breaking. The 100 rails are also usually made from carbon steel, which is a type of steel with a high carbon content. Carbon steel rails are very strong and durable, making them suitable for heavy freight transportation. Some 100 rails are also made of stainless steel. Stainless steel rails have a high chromium content, making them resistant to rust and corrosion. Stainless steel rails can last longer in harsh environments where rails are often exposed to moisture and chemicals.

Size:

100 rails have different sizes, with the number indicating the profile shape on the rail. The height of the rail is measured from the bottom of the web to the top of the head. The 100 rails have a height of 100 mm (3.937 inches). The width of the head is the distance between the two edges of the head. The 100 rail has a head width of 58 mm (2.283 inches). The web is the vertical section between the head and the base. The 100 rail has a web thickness of 6 mm (0.236 inches). The base is the bottom section of the rail that is fastened to the railroad ties. The base width for the 100 rail is 152 mm (5.984 inches). The length of the rail is measured from one end to the other, and the 100 rails have different lengths ranging from 12 to 30 meters (39 to 98 feet). The weight of the rail is also specified because it affects the amount of freight it can carry. The 100 rails weigh 56 kg/m (115 lbs/yard).

Here are some general rules for maintaining the 100 rail:

Regular inspections:

It is important to regularly inspect factors like rail wear, rail joint conditions, track alignment, vegetation and obstacles, and drainage systems. Regular inspections help identify and address potential problems before they become serious.

Vegetation control:

Users should control the growth of vegetation along the railway line. This is because overgrown vegetation can obstruct visibility and access to the railway tracks. In addition, overgrown vegetation can cause interference with railway operations.

Rail lubrication:

Regular lubrication of the 100 rail joints and switches is important to reduce friction and wear. Using the right lubricant helps ensure smooth operation and prolong rail infrastructure. Rail lubrication helps reduce maintenance costs and improves railway safety.

Drainage maintenance:

Drainage systems along the 100 rail are important for managing water runoff and preventing flooding. The water drainage systems should be regularly maintained to ensure they function properly. This involves clearing debris, inspecting for damage, and repairing drainage channel pipes.

When investing in a 100-rail, consider functionality, material, and customization options. These are the most important factors that will affect the quality of the rail and how well it will serve its purpose.

Think about what needs the 100-rail is supposed to fulfill. Is it for an interior space, outdoor use, or both? Understanding the intended use will help narrow down the options. For instance, if it's for outdoor use, durability and weather resistance are key factors.

The material of a 100 rail is important because it affects its strength and resilience. Common materials include wood, metal, and composite materials. Wood offers a traditional and attractive appearance and can be used for both indoor and outdoor applications. However, it requires regular maintenance to prevent decay and damage from insects. Metal rails are strong and durable. They are ideal for places that need high security, like industrial settings. They are also good for outdoor use because they don't break down. Composite materials combine the advantages of wood and plastic, making them low maintenance and versatile.

Check if the 100 rail can be customized to meet specific needs. Some manufacturers offer options for changing the size, design, and features of the rail to align with preferences.

Consider the installation process of the 100 rail and whether professional installation will be needed. Some rails are easy to install as DIY projects, while others require expert installation due to their complex design.

Installing a 100 rail can be a DIY-friendly task. However, some tasks may be complex, and DIYers may need to consult professionals. Here are some simple steps for installing 100 gun rails.

Preparation

Gather all the necessary tools for the project. Find a suitable workspace with adequate lighting to ensure safety. Make sure the firearm is unloaded and adhere to all safety measures.

Selecting Rail Type

Choose the appropriate rail type that suits the firearm. Select the mounting options that are within the DIYers capabilities.

Mounting the Rail

Follow the manufacturer's instructions to mount the rail. If one is using screws, drill the holes and tap the screws gently. If one is using adhesive, prepare the surfaces and apply the adhesive.

Alignment and Leveling

Ensure that the rail is properly aligned and leveled. Use a measuring tape or level to verify that the rail is aligned with the firearm's features.

Securing the Rail

Secure the rail once the alignment is complete. Tighten all screws or bolts carefully. If one uses adhesive, make sure to hold the rail in place until the adhesive cures.

Finishing Touches

Clean the firearm and the surrounding area. Ensure that all tools and materials used during the process are removed. Perform a safety check on the firearm to ensure proper functioning.

Q1: What is the difference between 100 rail and other types of rails?

A1: The only difference is the size. The 100 rail is smaller and suitable for lightweight applications.

Q2: Can one use 100 rail for heavy-duty applications?

A2: It is not advisable to use the 100 rail for heavy-duty applications. If the task is lifting heavy equipment, users should consider upgrading to a larger rail size.

Q3: Are 100 rails compatible with other rail sizes?

A3: Yes, it is possible. However, mismatched rail and fitting sizes can lead to operational inefficiencies and safety risks. Always ensure compatibility before use.

Q4: Can 100 rails be used in outdoor environments?

A4: Yes, the 100 rails can be used in outdoor environments. However, users should select materials with suitable corrosion resistance, such as stainless steel, to withstand harsh conditions.

The keyword "100 rail" has demonstrated a consistent web search volume trend over the past year, with an average monthly web search volume of 10. This keyword has shown no percentage change in the last three months or over the past year, indicating stability in interest levels.

Analyzing the detailed monthly data for "100 rail" reveals that the web search volume has remained constant at 10 web searches each month from December 2023 to November 2024. This pattern suggests a steady demand with no significant fluctuations or seasonal variations affecting search behavior.

The consistent web search volume for "100 rail" could be attributed to a stable market demand or a niche user base that requires this specific type of rail for particular applications, such as in specialized industrial or construction projects. This steady interest level underscores the importance of maintaining a consistent online presence to cater to the needs of this targeted audience.